Turbochargers

A turbocharger improves the volumetric efficiency of an engine. Because a turbocharger is driven by expanding exhaust gases, it is a free boost source.

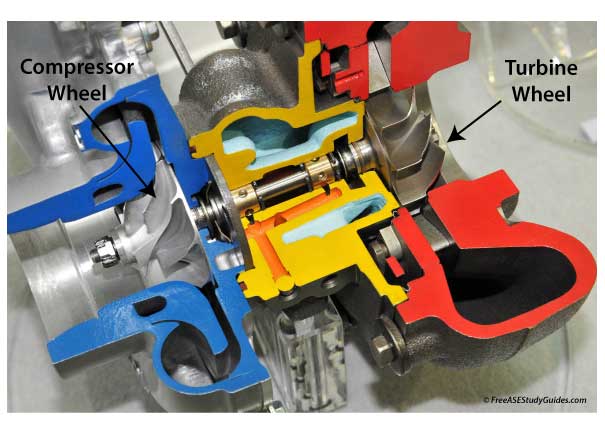

Expanding exhaust gases drive the turbine wheel. It's fastened to a shaft that spins the compressor wheel. The compressor wheel compresses the air-fuel charge in the intake manifold. This compressed charge is denser than the charge in a normally aspirated engine.

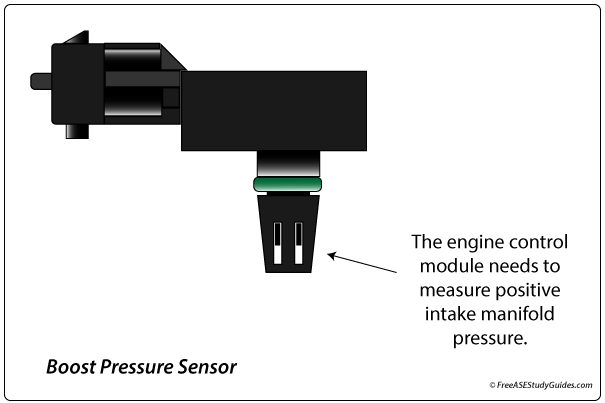

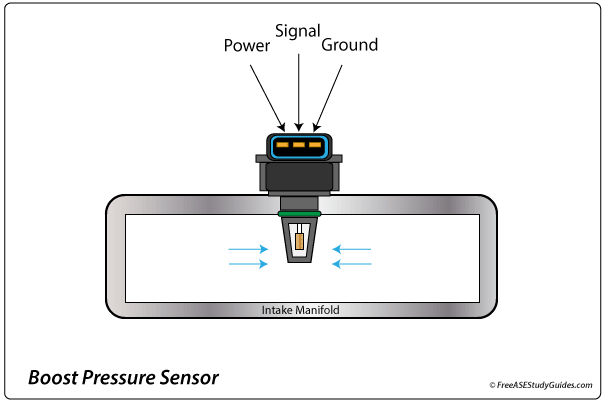

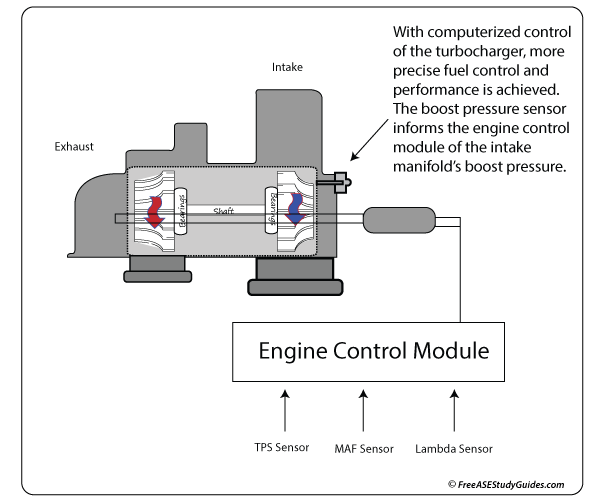

Boost Pressure Sensor

Turbocharged engines contain a Boost Pressure Sensor similar to a Manifold Absolute Pressure Sensor. Others have both a BPS and a MAP. The engine control module needs to measure positive and negative intake manifold pressures.

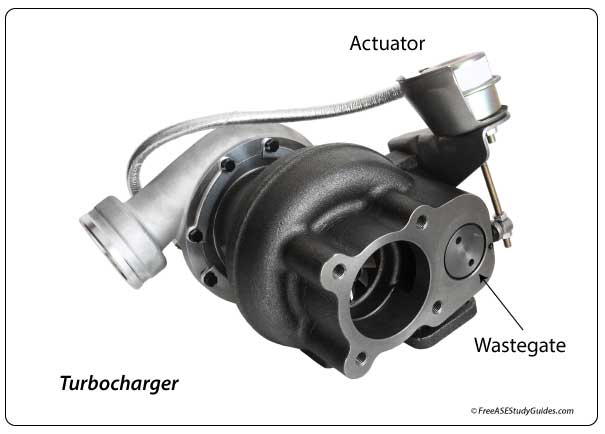

The turbocharger boost pressure is measured by a boost pressure sensor and regulated by a spring-loaded valve in the body or a wastegate and computer-controlled solenoid. When opened, the wastegate diverts some of the exhaust away from the turbine wheel, depriving it of exhaust pressure. Excessive manifold and cylinder pressures would damage vital engine components without this necessary reduction in output. The wastegate closes once boost pressure is under control and reaches normal operating pressure.

The Turbocharger Wastegate

An underboost condition usually occurs when the wastegate stays open or opens too early. A sticking wastegate or wastegate linkage will also result in an underboost. A restriction in the exhaust will reduce exhaust flow past the turbine wheel, resulting in this condition. Underboost results in poor acceleration and a loss of horsepower.

The ECM controls an electric solenoid-operated vacuum valve that moves the wastegate diaphragm. A partially open or closed wastegate from a faulty valve, a disconnected vacuum line, or a leaking diaphragm will cause an overboost condition. Overboost can damage the turbocharger and the engine.

Turbocharger Bearing Failure

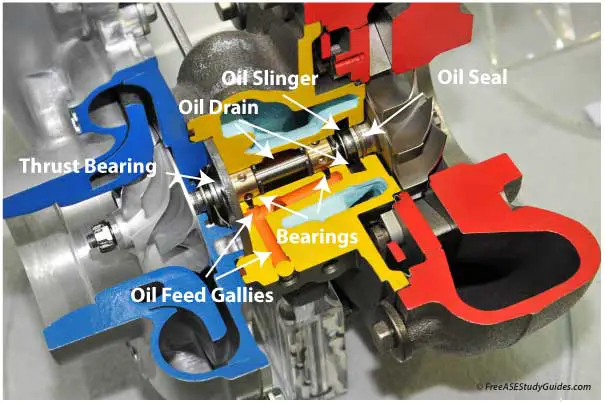

Excessive crankcase pressure, shaft end-play, a clogged or restricted oil drain, and oil seal failure result in oil entering the turbine housing—the burning oil results in the blue-gray exhaust. In addition, if the oil is restricted and is not draining to the oil pan properly, it can back up into the compressor and leak past the oil seals.

Premature failure is typically due to a lack of maintenance or contaminated and unchanged oil, resulting in bearing damage. Turbocharger bearings spin at very high speeds; they quickly overheat if not lubricated sufficiently. Worn and faulty bearings rapidly lead to damaged seals and blue-gray exhaust.

Turbocharger Maintenance

Turbocharged engines are port-injected and have a lower compression ratio than standard engines. The parts are usually not interchangeable. The engine's cooling system keeps a liquid-cooled turbocharger cool. The cooling system lines to the charger must be maintained and functioning correctly. Check the air tube for obstructions and that the air filter is clean. Dirt passing the air filter can damage the compressor blades.