Variable Valve Timing

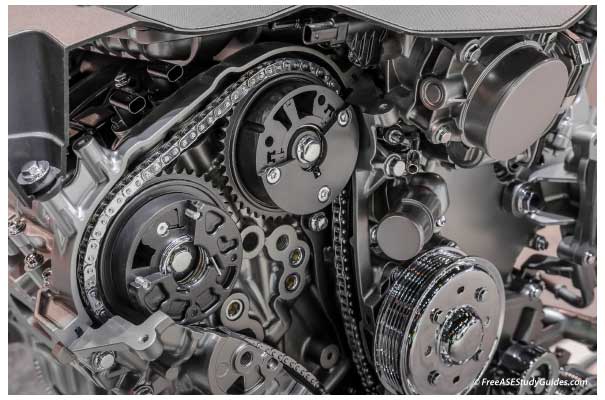

Most late-model vehicles have some form of (VVT) variable valve timing. Variable valve timing delivers smooth idle and low-speed operation and performance and horsepower at higher RPMs.

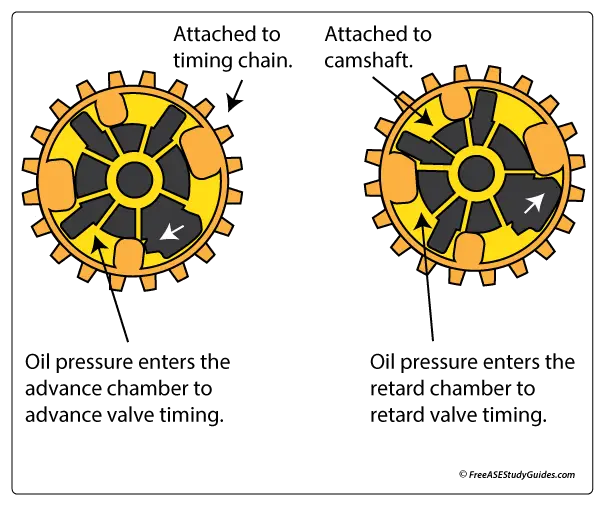

There are different ways to accomplish this. Some systems change the timing by opening the intake valve sooner, allowing more air-fuel mixture to enter the combustion chamber.

Alternating between two camshaft lobes for each cylinder provides a smooth idle, low-speed, and high-speed performance.

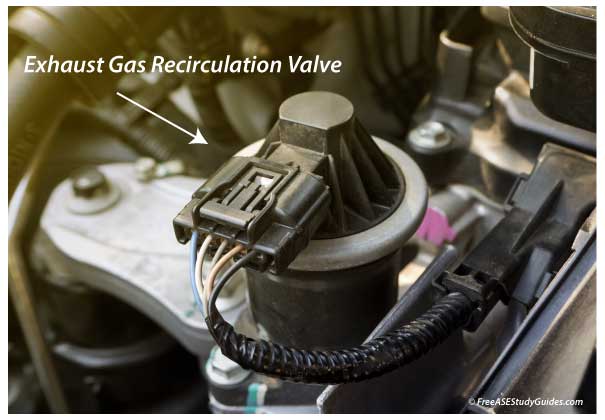

Holding the exhaust valve open a little longer allows a small amount of exhaust to enter the chamber, reducing NOx formation. As a result, manufacturers have designed engines without EGR valves.

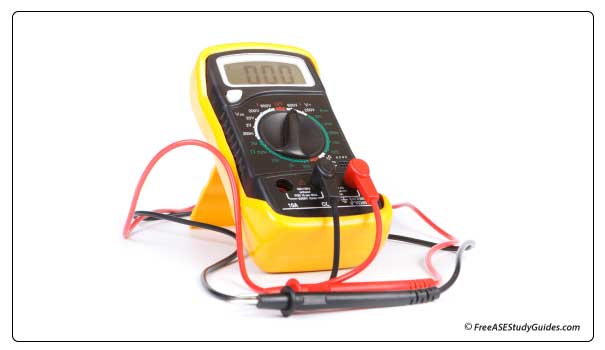

Test the solenoid and its circuit for resistance with an ohmmeter. A faulty VVT solenoid or valve could produce a rough idle or poor high-speed engine performance. The solenoids and actuators that control these systems can become clogged or have electrical issues. Unchanged oil is a big problem. The solenoids, control valves, and passages become clogged with a gel from neglected and unchanged oil. A tarnished actuator may not release or engage.