Manual Transmission Bearings

Manual transmissions contain different types of bearings. Each type has a unique purpose and application. Due to their design, tapered roller bearings are used at the ends of the transmission shafts. There's a preload applied. Check with the vehicle manufacturer for specifications.

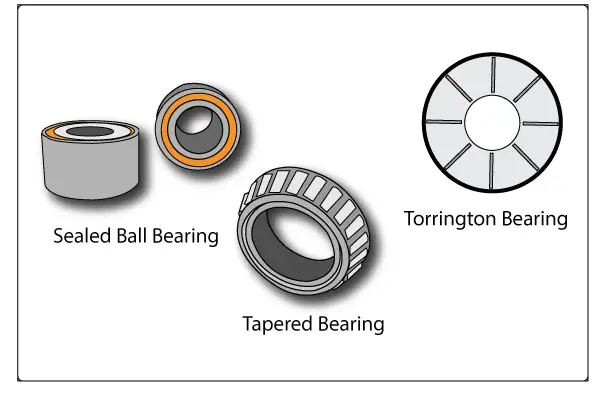

Ball Bearings: Ball bearings consist of small steel balls separated from each other by a steel cage. They're capable of withstanding both radial and axial loads. Ball bearings provide for the smooth operation of high-speed components like axle shafts.

Roller Bearings: Roller bearings have more surface area than ball bearings. These bearings are well-suited for heavy applications. Tapered roller bearings are used in differentials, final drives, and transfer shafts and require a slight preload. Always check the vehicle manufacturer's specifications before setting preload on a tapered roller bearing.

Needle Bearings: Needle bearings consist of small needle-like bearings. These small bearings are held in a round cylinder by assembly grease. Handle carefully; needle bearings are not fastened to the cylinder and can fall from the carrier. Use petroleum jelly or Vaseline to replace and hold any fallen bearings.

Torrington Bearings: A different design of needle bearing called a Torrington bearing contains small needle bearings in a cage. They are also known as caged needle bearings. The bearings are placed in a spoke pattern like a bicycle wheel inside a thrust washer. They reduce friction while controlling shaft end play.

Thrust Washers: Thrust washers adjust and control shaft end play. Use selective washers and a dial gauge against the end of a shaft or gear to adjust end play.

Never use white, chassis, or bearing grease when installing bearings and washers in a transmission. These greases do not mix well and may contaminate the manual transmission fluid.