ASE A3 Manual Drive Train and Axles

11. A manual transmission makes a grinding sound at the front of the transmission with the engine running and the clutch fully engaged. Which of the following is causing this noise?

- A. A faulty input shaft bearing.

- B. A faulty output shaft bearing.

- C. A faulty clutch release bearing.

- D. A faulty pilot bearing.

12. Which of the following are placed at the ends of the transmission shafts and require a slight preload?

- A. Sealed ball bearings.

- B. Thrust bearings.

- C. Tapered roller bearings.

- D. Needle bearings.

13. A 4WD vehicle makes a popping sound when accelerating from a stop. This sound only occurs in 4WD. Which of the following is causing this condition?

- A. Low engine vacuum.

- B. A faulty shift motor.

- C. A stretched transfer case chain.

- D. A faulty relay.

14. A vehicle has an excessive vibration at highway speeds. Technician A says to use a dial gauge to measure the driveshaft for runout. Technician B says to use a dial gauge to test the driveshaft companion flange for runout. Who is correct?

- A. Technician A

- B. Technician B

- C. Both A and B

- D. Neither A or B

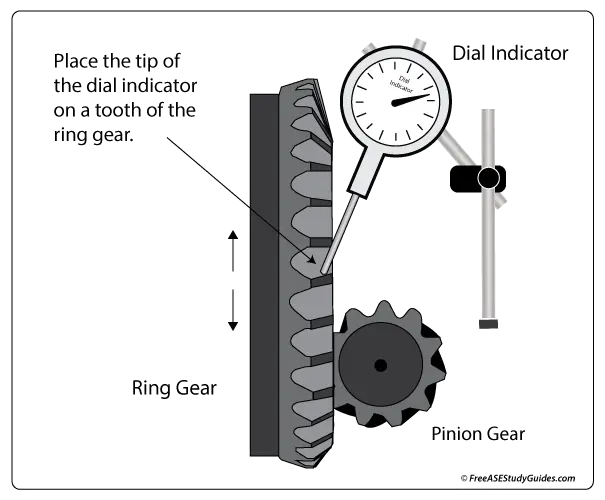

15. The measurement taken in the illustration above is checking:

- A. Ring gear runout.

- B. Pinion bearing preload.

- C. Ring gear backlash.

- D. Ring gear tooth contact pattern.