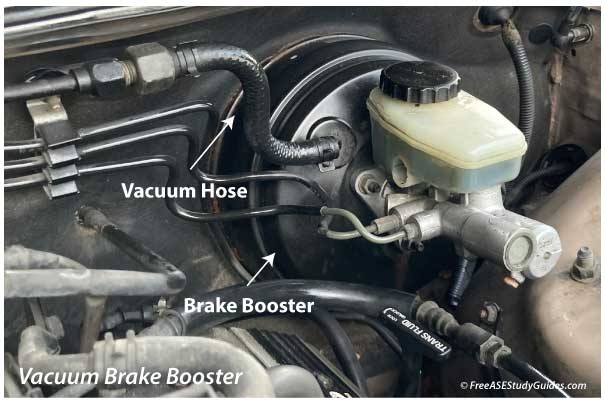

Vacuum Brake Booster Diagnosis

A vehicle with a faulty or leaking brake booster will likely have a hard brake pedal and diminished stopping power. A leaking check valve or hose, the booster pressure sensor, and the vacuum pump are all parts of the system that can affect a vacuum brake booster operation.

Brake Booster Operation

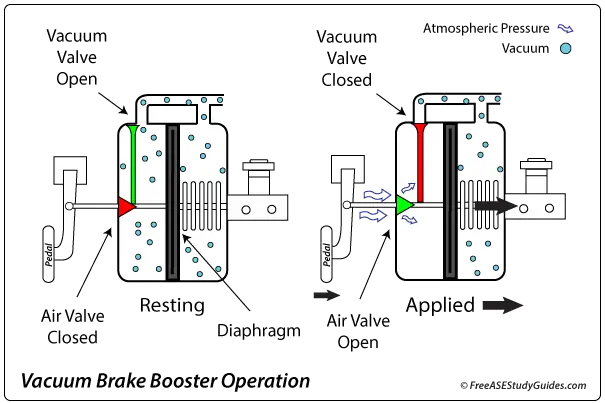

A vacuum-operated brake booster has two chambers, one on the brake pedal side and one on the master cylinder side, separated by a diaphragm. A one-way check valve allows and holds the vacuum pressure in the booster.

The brake pedal controls the air and vacuum valves on the booster's peddle side. The air valve allows outside air into the chamber while simultaneously, the vacuum valve cuts the vacuum off. The difference in pressure between the pedal side and the master cylinder side (assists) the power piston towards the master cylinder, significantly reducing the effort required to apply the brakes.

Testing a Vacuum Brake Booster

Always do a complete visual inspection and ask the customer about the braking complaint. Check if the vehicle has a hard brake pedal and is having difficulty stopping; if so, suspect the brake booster. Turn off the engine, pump the peddle 20-25 times to deplete the vacuum (check the manual if unsure), and start the engine. If adjusted correctly, the pedal should move a specified amount (an inch or two) towards the floor. Always check the vacuum supply and compare it with the manufacturer's specifications.

Start the engine and let the booster build pressure. Press down and hold the brake pedal firmly. Turn off the engine. A good vacuum booster will hold the vacuum and should not lose pressure or press back on the pedal for ~ 30 seconds. If the brake booster leaks, the pedal will push back toward the driver's foot after the engine shutdown. Check with the vehicle's manufacturer for pattern failures, TSBs, or special procedures.

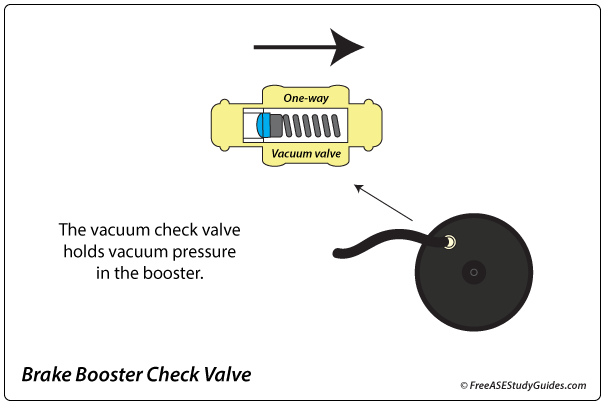

Vacuum Check Valve

The check valve and hose allow vacuum pressure into the booster and hold it in at wide open throttle and after engine shutdown. Remove the valve and check its one-way function by applying pressure to both sides; it should allow flow in one direction and block flow in the other. Install a vacuum gauge into the check valve end of the vacuum hose. Start the engine and measure intake manifold pressure (18-21 Hg).

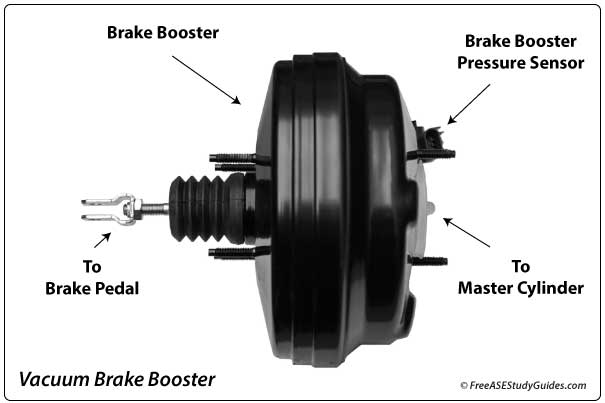

Brake Booster Pressure Sensor

Not all engines produce enough vacuum in the manifold to maintain pressure in the booster. Therefore, manufacturers have installed electric, belt, or cam-driven pump units to create vacuum pressure for the booster.

A brake booster pressure sensor and the control module monitor the vacuum pressure in the brake booster. The control module activates the vacuum pump when the vacuum is low. A problem with the sensor will illuminate the check engine or brake warning light. Symptoms of a faulty brake booster pressure sensor include a stiff brake pedal and a vehicle with little stopping power.