Turbocharger Leaking Shaft Seals

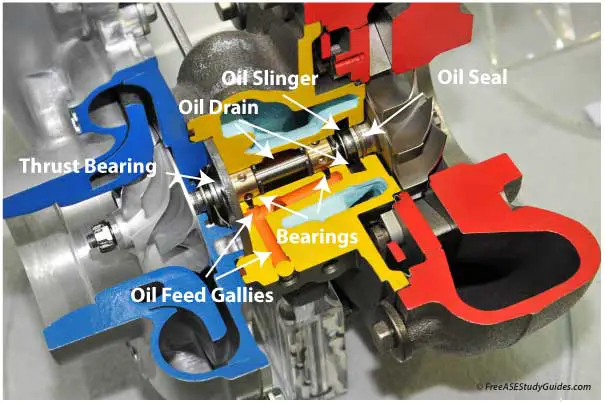

Turbocharger oil seals are not rubber o-rings. Instead, they are heat-resistant steel rings that resemble piston rings. They have a small gap at the ends and are springy for a tight fit. Most oil drains to the sump directly after cooling and lubricating the bearings. The oil slinger deflects most of the oil before reaching the oil seal by slinging it outwards and down the drain.

Heat soaking into the charger after shutdown causes the oil to change and harden inside the seal. This process is known as coking. Turbo coking occurs when the engine first shuts down and there is no oil flow. Water-cooling and merely letting the engine idle and cool down can lengthen the turbocharger's lifespan.

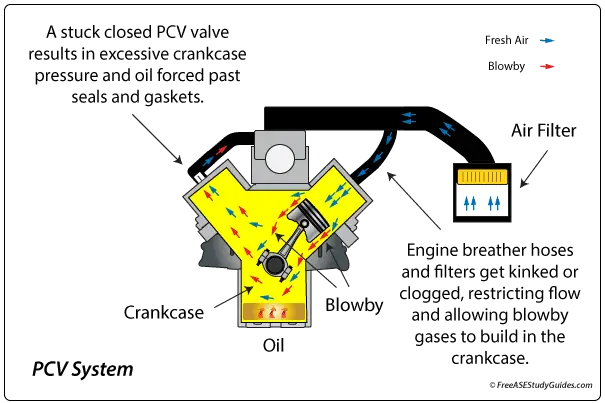

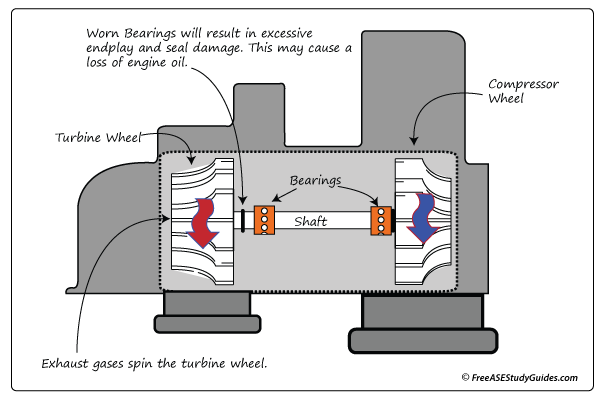

Excessive crankcase pressure, shaft end-play, a clogged or restricted oil drain, and oil seal failure result in oil entering the turbine housing—the burning oil results in the blue-gray exhaust. In addition, if the oil is restricted and is not draining to the oil pan properly, it can back up into the compressor and leak past the seals. Excessive crankcase pressure caused by a faulty PCV system or clogged breather causes the oil to leak past the oil seals.

Turbocharger Center Housing

Oil flow is vital. If there is a lack of lubrication, the center housing will soon make a growling or high-pitched whining noise caused by bearing failure. It also damages the shaft, the wheels, and the housing. In addition, excessive end-play causes the wheels to contact the inside of the turbine and compressor housings.

The engine's oil lubricates the turbocharger. Changing the oil and coolant at recommended intervals is vital to a turbocharger's life expectancy. Today's turbochargers spin well over 100,000 RPM. These speeds create substantial heat that wears on oil.