Steering Gear Adjustments

Check the torque measurements with an inch-pound torque wrench before adjusting. Then, set the input shaft/worm gear thrust bearing preload and the sector lash adjustment to specifications.

The first adjustment is the input shaft/worm gear thrust bearing preload. The terms input shaft and worm shaft indicate the same part, just different names.

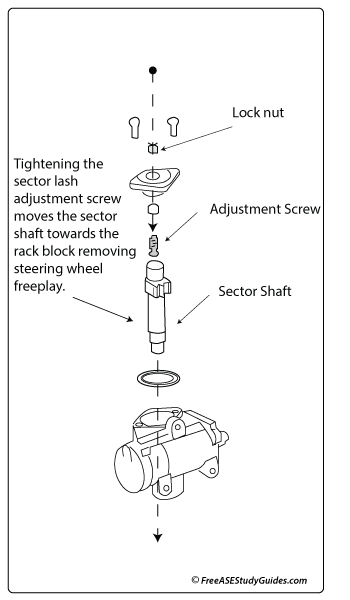

The second adjustment is the sector lash adjustment. Always use the manufacturer's recommended procedures and specifications. This adjustment removes any worm shaft axial end play while providing the least resistance to the shaft's movement. This adjustment is measured using an inch-pound torque wrench.

The sector shaft lash adjustment is made after the worm shaft bearing preload adjustment. Turn the adjustment screw in and out of the gearbox's top plate. Look down over the fender at the top of the steering gear to find the plate. The manufacturer's procedure will typically center the stub shaft before adjusting the sector shaft.

Loosen the lock nut and turn the adjustment screw in to decrease the lash and remove any looseness in the wheel. This measurement is sensitive, usually around 5-6 inch-pounds at the ends, and may increase to 10-12 inch-pounds in the center. Always check with the vehicle manufacturer's specifications before setting the lash.