Air Fuel Ratios

A (14.7:1) air-fuel ratio is considered the perfect blend or stoichiometric air-fuel ratio where there is just enough air (14.7) to burn one part of fuel with no excess oxygen or fuel left over.

Faulty components such as dripping fuel injectors, fuel pressure regulators, ECT, and stuck open thermostats result in high emissions (HCs) and black-colored exhaust.

Fuel Injectors: Fuel injectors atomize and inject pressurized fuel from the fuel rail into the cylinders. They can become clogged with deposits that form as the remaining fuel dries in the injector's hot tip as the engine cools. They can also leak or drip pressurized fuel. Check for dripping fuel injectors by performing a leak-down test with a fuel pressure gauge.

Fuel Pressure Regulator: A fuel pressure regulator provides steady fuel pressure to the fuel injectors under different loads and operating conditions. A traditional regulator contains a vacuum-operated diaphragm controlled by the intake manifold's vacuum. Electronic regulators do the same thing with more precise computer control.

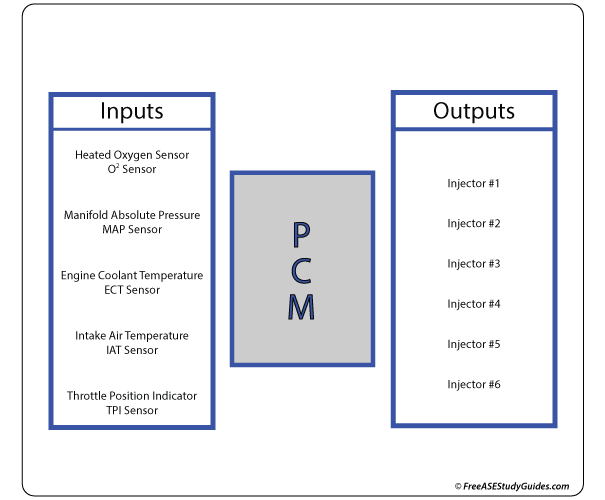

Engine Coolant Temperature Sensor: The ECT informs the ECM of the engine's current operating temperature. This temperature is essential to the air-fuel mixture during cold starts because a cold engine requires a richer air-fuel ratio. Therefore, a corrupt signal indicating a colder than an actual engine will result in a rich air-fuel mixture.

A faulty oxygen sensor sending the wrong signal to the engine control module can result in a rich fuel condition. Symptoms include black-colored exhaust, fouled spark plugs, and poor engine performance.