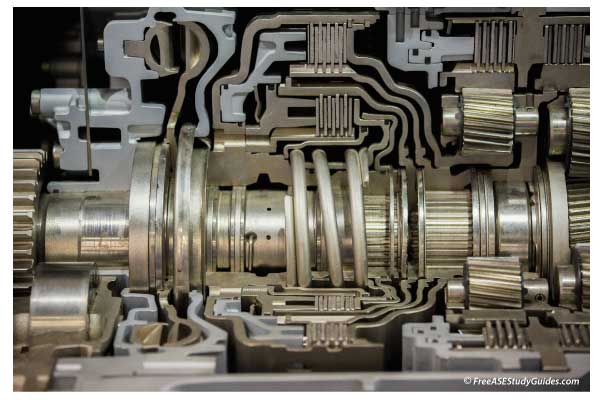

Multiple Disk Clutch Assembly

Automatic transmission multiple disc clutch assemblies are wet clutches that drive and hold the planetary gearset members. Friction discs are splined on the inside, fastening them to one set member, a hub, or a drum. They are cellulose, with grooves cut into their surface to aid heat dissipation or semi-metallic or metallic materials. Metal friction discs wear their mating steel plates sooner than paper discs. Steel separator plates are splined on the outside and slide on the splines/lugs inside the case or drum.

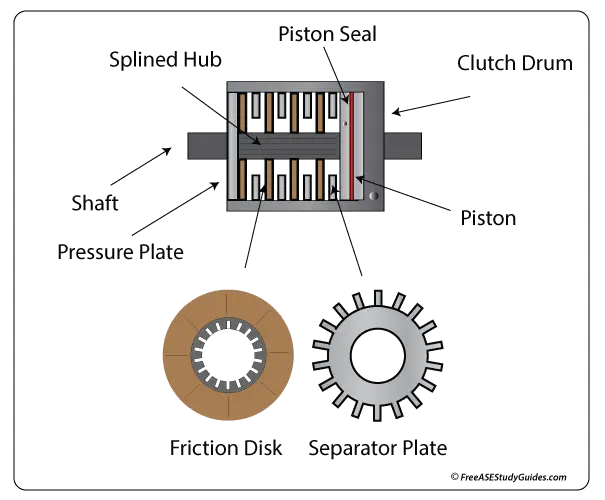

Multiple Disk Clutch Components

When a clutch is case-held, the outer splines slide into slots in the transmission case. A member is locked to the case when the clutch assembly is applied. This clutch type is considered case-held, grounded, or "locked." When hydraulic pressure is released, a spring or set of springs returns the piston assembly to its parked position.

Some residual pressure is left after the venting of the hydraulic pressure. It's released through a vent, check ball or a controlled orifice inside the drum. If the ball doesn't rattle around when the drum is shaken, it's probably stuck from tarnish. This problem results in excess pressure on the clutch and premature wear.

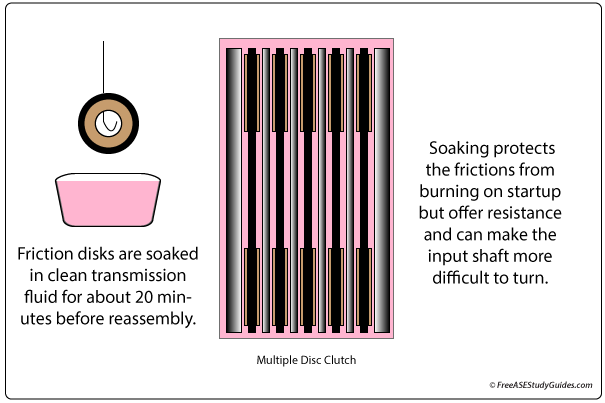

Clutch Friction Discs

When disassembling a transmission, it's important not to mix the parts of one clutch pack with another. Always inspect and clean the assemblies after removal. Typically, friction discs are soaked in clean transmission fluid for about 20 minutes before reassembly. The soaking protects them during initial use. Review manufacturer specifications for proper clutch pack clearances, TSBs, or special test procedures.