Main Bearing Caps

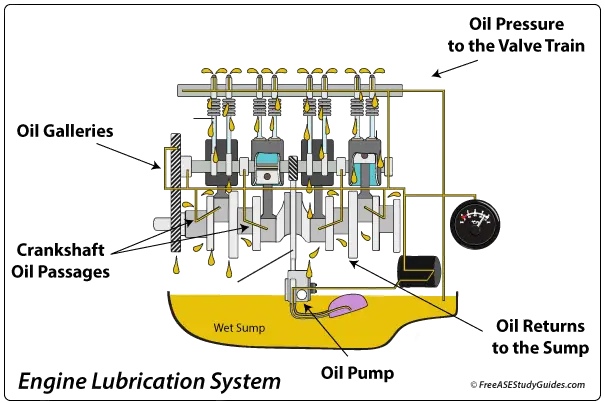

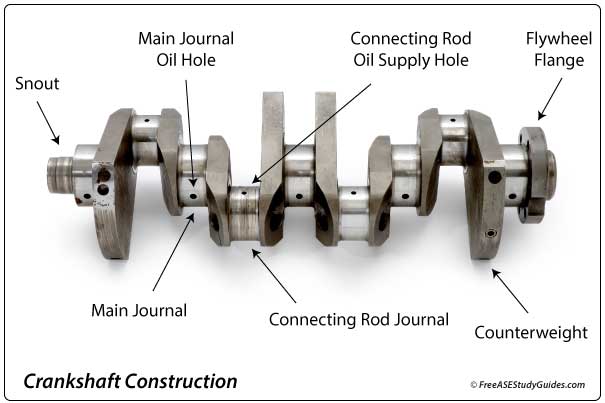

Crankshaft bearings have a soft metal coating that rides on a thin layer of pressurized oil. The oil pump sends pressurized oil through holes drilled through the crankshaft to the bearing surface. They allow oil to flow through the clearance between the bearing and the crankshaft journal. Fresh pressurized oil flows into the gap and past the bearing's edges. This oil creates a cushion that absorbs the downward force created by the engine's power stroke.

When the coating wears, the bearing and the crankshaft journal are unprotected. Underneath the metal alloy coating is a brass-colored metal. If the bearing has worn past specifications and the gap has increased, brass will appear on the bearing's surface.

Remove and inspect the oil pan for debris and remove bearing caps to inspect the bearings for wear. When brass appears on the bearing surface and in the oil pan, the metal coating is missing, and the bearings need replacement.

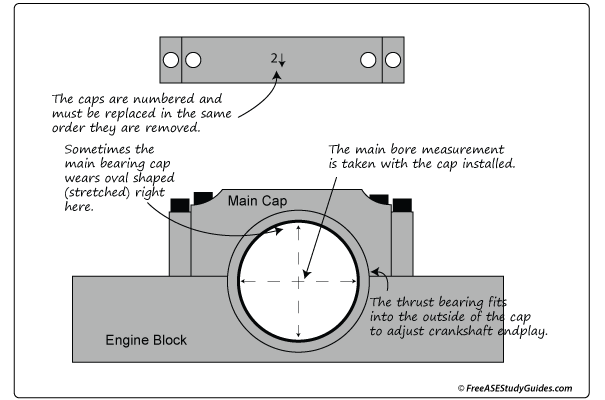

The main caps and journals are inspected and measured before replacing the worn bearings. The main caps become oval from the intense downward pressures imposed by the engine's crankshaft.

Inspection: Each cap is bolted in place before a line boring tool bores the main bore through the bottom of the engine block and the main bearing caps at the factory. This process is why keeping these caps in order is so important. The main caps have numbers and arrows pointing toward the front of the engine. Whenever working with an engine part, arrows or indented dots typically point toward the front of the engine. Check the appropriate manual for proper procedures before taking measurements.

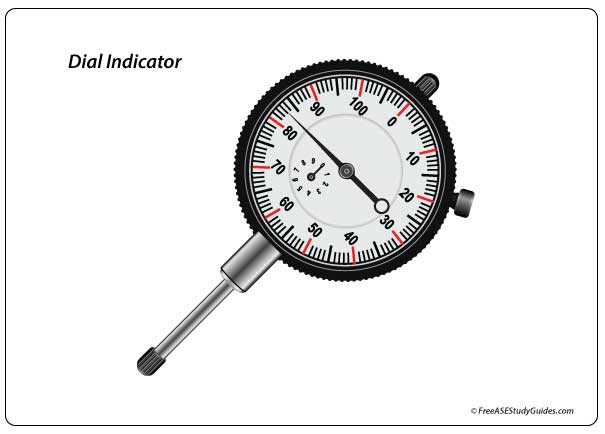

Measure the crankshaft end-play with a dial indicator mounted on the engine and the indicator's tip on the flange. Use a pry bar or a large screwdriver to move the crankshaft back and forth. It is important to check these measurements before and after a rebuild. Thrust bearing thickness controls crankshaft end play. Clearance should be minimal.