Final Drives

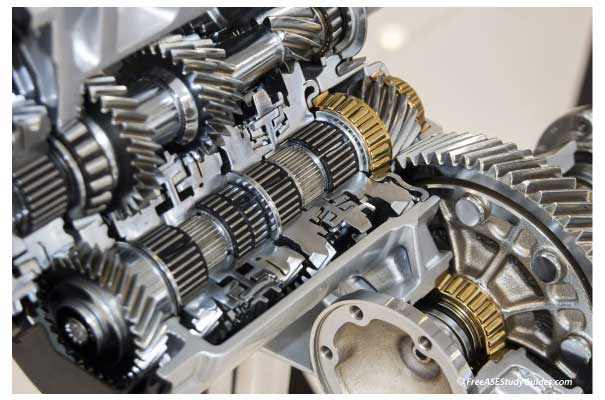

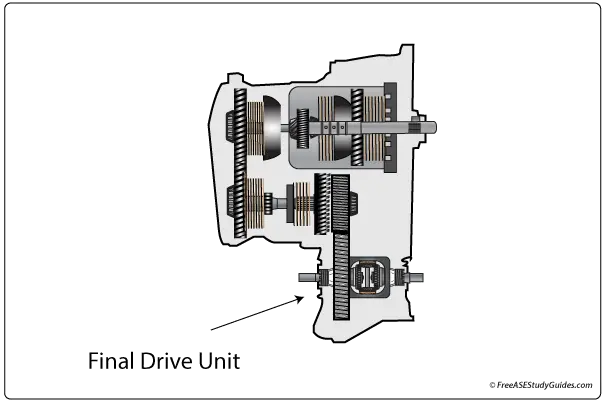

Transaxles combine the transmission with the final drive unit in the same housing. The final drive is the last set of gears in the transaxle, performing the same function as those found in rear-wheel-drive vehicles.

Some transaxles use a gearset, and others use a chain and sprockets to drive the transfer gear. Check the chain for play or slack by deflecting it using a screwdriver, marking the case, then moving it down and marking it again. The sum of the two is the total amount of chain slack. Check the manufacturer's specifications. There's typically a slight deflection in a good chain.

Many transaxles use transfer gears instead of drive chains to achieve the same results: power transfer from the output shaft to the transfer shaft.

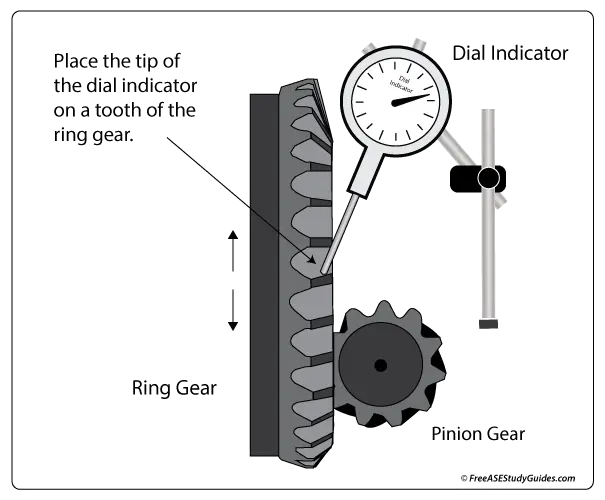

Check ring gear backlash with a dial indicator. Always compare readings with manufacturer specifications.