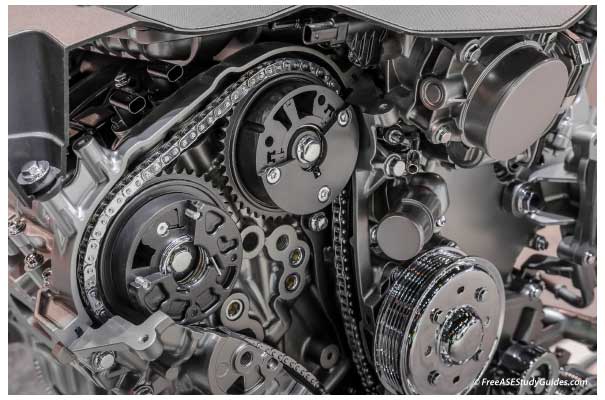

Variable Valve Timing

The valves in an engine with variable valve timing operate independently of crankshaft rotation. As a result, VVT delivers smooth idle and low-speed operation, better performance, and more horsepower at higher RPMs.

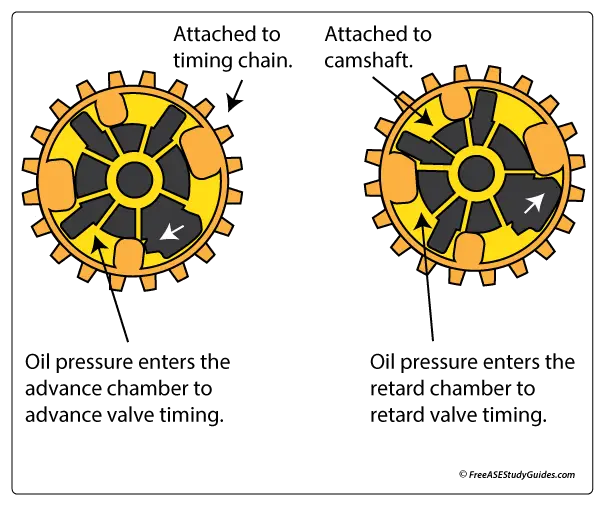

There are many designs in automobiles today. The ECM controls the cam phasers to rotate the camshaft, advancing or retarding the valve timing. This design does not affect the valve lift or duration.

The VVT solenoids alter hydraulic pressure between the advance and retard chambers to rotate the camshaft and adjust valve timing.

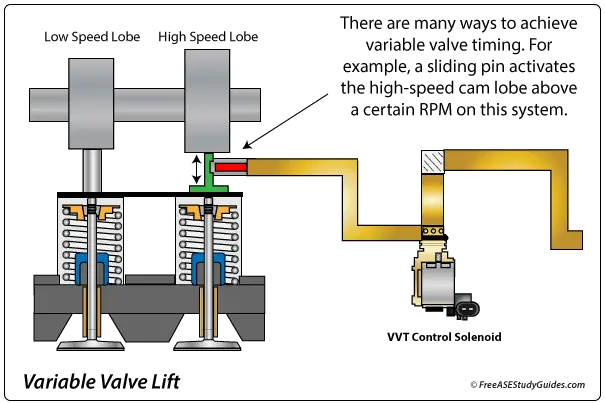

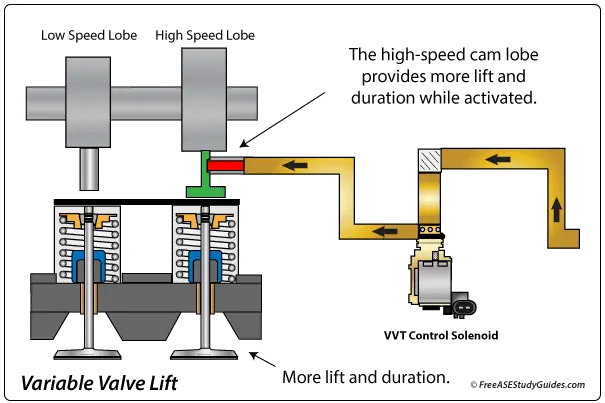

Variable Valve Lift

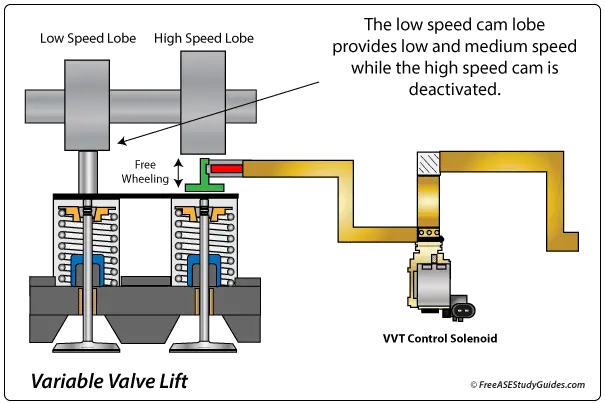

The VVL or variable valve lift system alters the valve lift and duration independent of crankshaft rotation.

The low-speed lobe provides a smooth idle and low-speed performance. An engine that combines VVT and VVL matches the valve timing, the lift, and duration through various operating conditions.

The high-speed lobe opens the intake valve further (lift) and longer (duration), increasing high-speed performance. Alternating between two camshaft lobes for each cylinder provides a smooth idle, low-speed, high-speed performance, and lower emissions.

Variable valve timing has many advantages. Holding the exhaust valve open longer allows a small amount of exhaust to enter the chamber, reducing NOx formation. As a result, manufacturers have designed engines without EGR valves.

Diagnosis

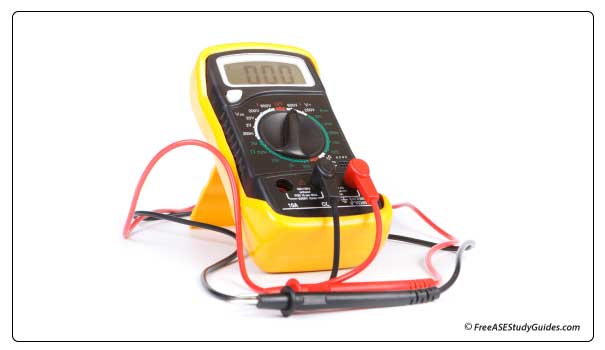

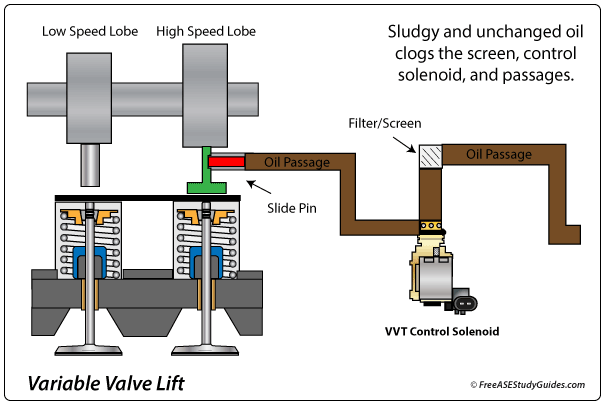

Use a scanner and an ohmmeter to test the control solenoid and its circuit. A faulty VVT solenoid or valve could produce a rough idle or poor high-speed engine performance. In addition, the solenoids and actuators used to control these systems can become clogged or have electrical issues.

Unchanged oil is a big problem. Today's engines have tight tolerances and use a thinner oil than older engines. Thick contaminated oil clogs the control valve, screen, and passages in the camshaft resulting in system failure.