Engine Cylinder Leakage

Cranking compression tests help identify cylinders with lower pressure than the rest. The cylinder leakage test helps pinpoint the area of concern and measures the amount of leakage as a percentage.

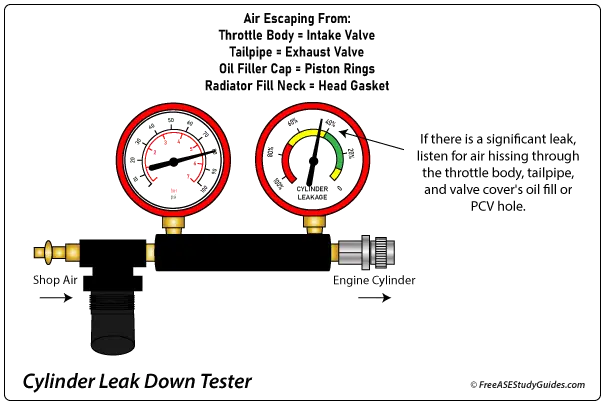

Perform a cylinder leakage test with a cylinder leak-down tester by injecting regulated shop air into the cylinder and measuring the drop in cylinder pressure.

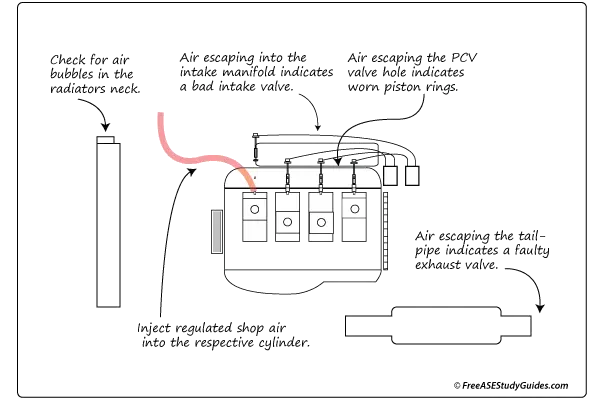

When there is excessive cylinder leakage, visually search and listen for a leak. The valves, rings, and head gasket seal the combustion chamber. The intake valve leads to the intake manifold, and the exhaust valve leads to the tailpipe. The piston rings lead to the crankcase and the PCV valve in the valve cover. Finally, the head gasket between the head and the block seal the cylinder and the engine's cooling system.

Troubleshooting Cylinder Leakage

The air-fuel charge no longer cools the intake valve with direct fuel injection. If the intake valve is not seated correctly, air escapes past the valve and into the intake manifold. It creates a hissing sound at the throttle body.

Air pressure escapes past the exhaust valve and out of the tailpipe. If air exits through the PCV outlet, the piston rings are faulty. If air bubbles appear from the radiator neck, the head gasket (most likely), the cylinder head, or the block's deck are at fault. Always refer to the manufacturer's specifications before performing any automotive test.