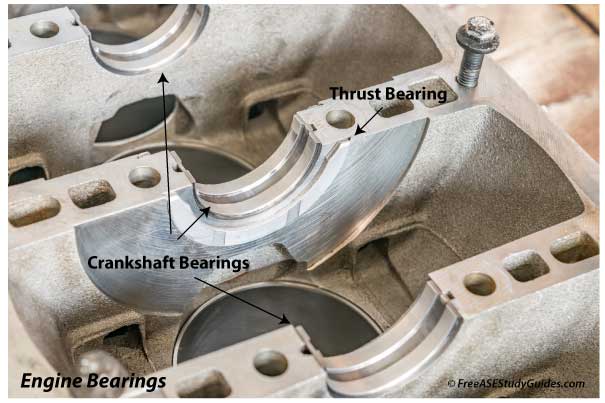

Crankshaft Bearings

Crankshaft bearings are a softer material than the crankshaft journal or cap. This softer metal ensures that the bearing material wears before the journal. A crankshaft journal does not ride on the bearing surface; instead, it rides on a thin film of oil between the journal and the bearing. There will be excessive wear whenever there is contact between the journal and the bearing. Excessive internal clearance caused by worn bearings and journals results in low oil pressure.

Check the bearing for metal particles embedded into its surface. These particles indicate that two metal parts are in contact, creating metal shavings. Find and repair this problem before proceeding. Look at the backside of the bearing insert for wear, indicating that it has spun in its saddle. Inspect the oil pump if metal shavings appear in the oil pan or the bearings.

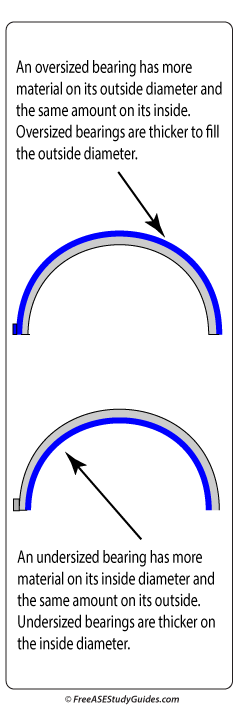

Check the main bearing bore for misalignment. There are several methods to do so. It is easiest to use a straight edge and a feeler gauge. Use a blade half the thickness of the maximum clearance. The feeler gauge must not fit between the straightedge and the surface of the bore. Warpage can be corrected if it is too far out of specifications. The block can be line bored and oversized bearings installed. The caps are numbered and usually have an arrow pointing toward the front of the engine. Never mix up the caps; doing so will result in out-of-round bore diameters.