Brake Lubricants

Lubricate rubber brake components with a high-temperature silicone or synthetic lubricant that does not contain petroleum products. Most manufacturers recommend using high-temperature, non-petroleum molybdenum or graphite-based lubricant with metal-to-metal components of a sliding caliper, like the shims or rails the pads slide on. These lubricants reduce vibrations and noises during brake applications. Without lubrication, excessive wear, squealing, and screeching sounds occur.

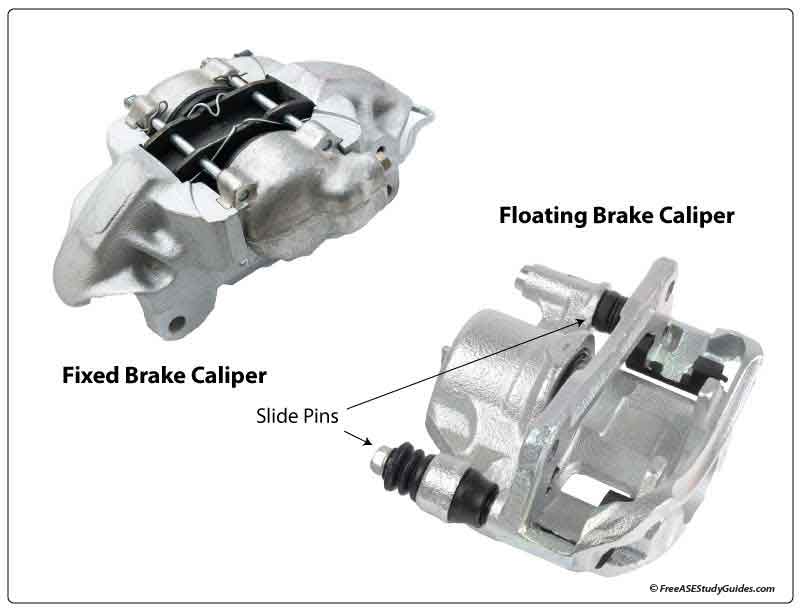

Brake Slide Pins

Many of today's brake systems utilize floating calipers that contain slide pins. These pins usually have a rubber bushing for smooth movement and support in the bore. Unfortunately, these rubber bushings and o-rings can swell from petroleum-based lubricants, inhibiting movement and prematurely causing the inboard pad to wear.

Dry Film Lubricant

Metal brake components like mount slides and backing plates also require high-temperature lubricants. A dry film lubricant containing solids like graphite works excellent on metal-to-metal parts. However, it's important to avoid getting any of this type of grease on rubber components. The rubber swells or deteriorates.

Rubber Brake Parts

Rubber and plastic brake components are especially vulnerable to swelling and deterioration. This is why using high-temperature silicone or a non-petroleum synthetic lubricant is so important. Other lubricants cause the rubber to swell, reducing slide pin movement and braking performance.