Torquing Lug Nuts

Over-torquing the lugs on a wheel can result in a warped brake rotor and possible hub flange damage. Rotors get extremely hot and improper, and over-torquing a wheel can result in warpage as the rotor heats up and cools back down in service.

Symptoms: Automotive technicians find themselves diagnosing brake rotors all the time. A warped rotor produces a noticeable vibration in the brake pedal, seat, and steering wheel at high and sometimes low speeds. As the pads squeeze against the rotating rotor, any variations or warpage in the rotor result in a vibration.

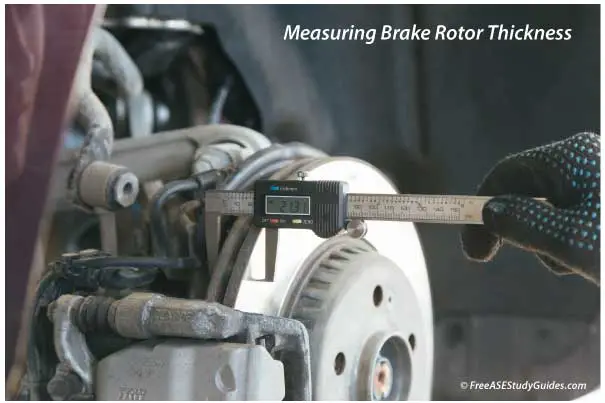

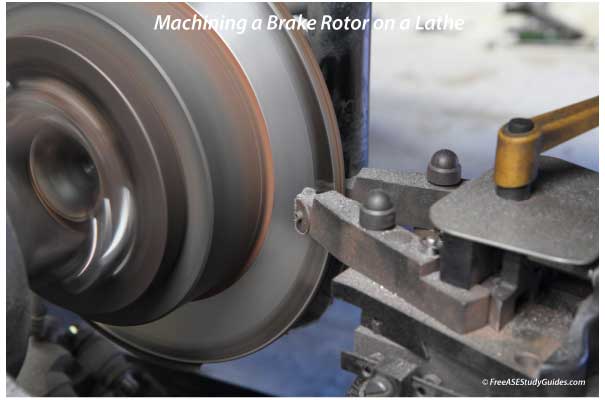

Thickness variation is common and often correctable. If within specs, thickness variation can be repaired by machining (turning) the rotor on a brake lathe. Check the thickness of the rotor before and after machining; a thin rotor will overheat and warp, ending in a return.

Use the correct torque limiting extension bar or torque wrench for accuracy. Warped front rotors result in a vibration that's felt most in the steering wheel. Warped rear rotors result in a vibration felt most in the seat and brake pedal.