Brake Metering Valves

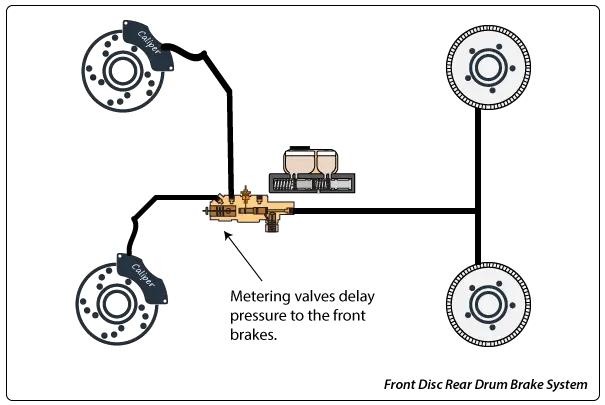

The drum brakes on vehicles with front disc/rear brake systems have stiff springs that retract and hold the rear brake shoes after brake application. A metering valve provides balanced braking by delaying the application of the front brakes, allowing fluid pressure to overcome rear brake spring pressure to engage just before the fronts.

Without this valve, the front disc brakes apply almost instantly while the rear brakes still must overcome spring pressure. The vehicle would nosedive. Nosediving is a symptom of a faulty metering valve and may cause vehicle instability and skid.

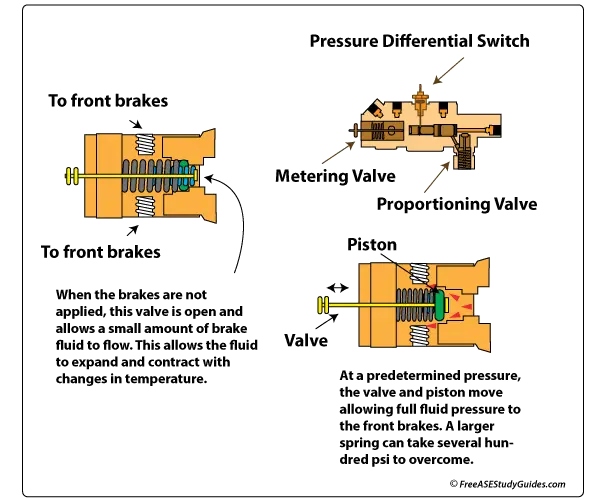

Open the bleeder screw to a front brake caliper and have a helper slowly apply the brake pedal. There should be a delay before fluid flows from the caliper bleeder. The metering valve holds off the pressure until the rear drum brakes have been applied. Use a pressure kit to test this delay and measure actual fluid pressures. Connect a pressure gauge to the inlet and another to one of the outlet ports. Compare the results.

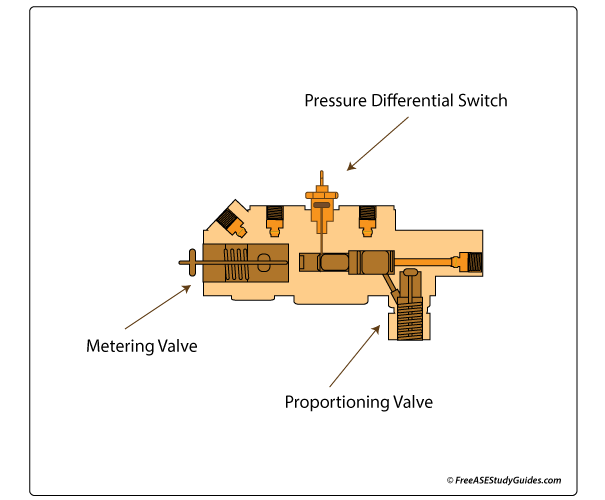

If air gets trapped in the brake line between the master and the metering valve, it can be difficult to bleed the brakes. Air is compressible, and pressure may not build high enough to open the valve. The metering valve above is in a three-way combination valve. The stem at the end of the valve is for bleeding trapped air. A small clip is used to open the valve and allow aerated fluid to bypass the valve and exit the system.