Binding Steering

The two steering gears commonly found on vehicles today are recirculating ball and rack and pinion. The recirculating ball steering gear is found on older vehicles and many of today's trucks. Rack and pinion steering gears are installed on front-wheel drive vehicles and light trucks.

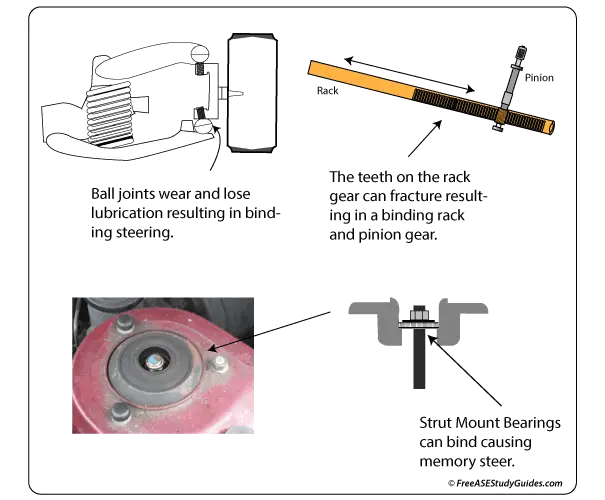

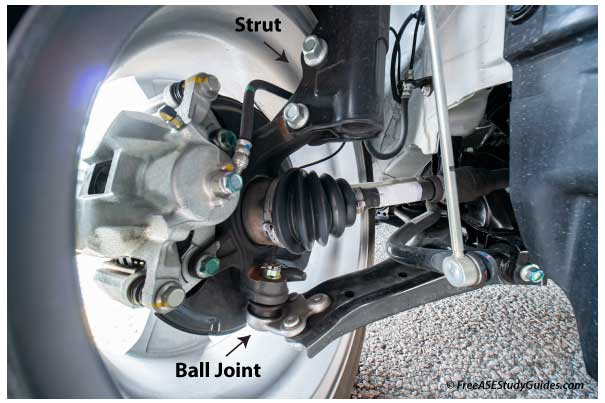

Binding steering while cornering is often caused by dry, worn ball joints. As the illustration shows, a binding ball joint, a binding rack gear, or binding strut mount bearings result in problem steering.

Loose Tie Rods

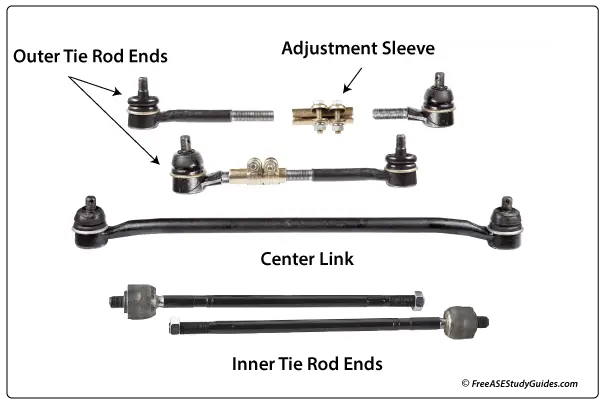

Worn tie rods produce noise, tire wear, and loose steering. The ball and stud have worn, and slack and looseness affect its performance. This looseness can affect either the inner or the outer tie rod ends. It results in vehicle wander and constant wheel correction to keep the vehicle in a straight line.

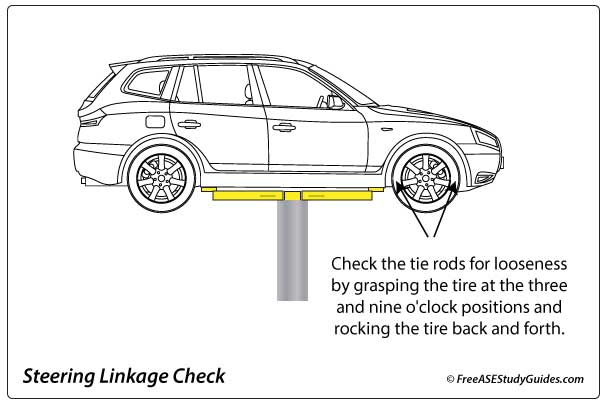

Check the tie rods by grasping the tire at the three and nine o'clock positions and rocking the tire back and forth. Safely raise the lower control arms instead of the frame with the hydraulic lift on an alignment rack.

Loose Rack Bushings

Rack and pinion steering gears are fastened to the firewall or frame with rubber insulation bushings (rack bushings). When these bushings become oil-soaked or worn, the gear will shift, changing the vehicle's toe setting and causing wander. This is because the rack now moves in its brackets. Steering wander is when a vehicle wanders left and right, causing the driver to compensate as the vehicle wanders back and forth down the road.