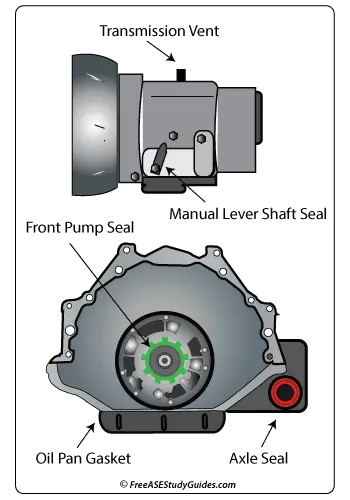

Automatic Transmission Seals

Automatic transmission seals contain fluid pressure and prevent leakage. They are metal, synthetic rubber, and Teflon and can be positive or non-positive. A positive seal contains all fluid. A non-positive seal allows a small amount of fluid to pass for the lubrication of moving parts.

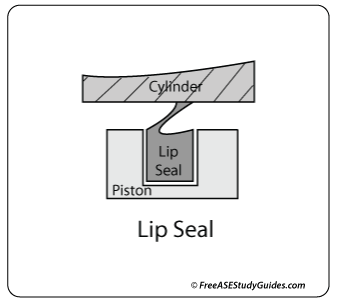

Lip Seals: Lip seals are ideal for both rotational and axial movement. They are used to apply pressure. Piston seals are a member of the lip seal family, vital to transmission performance. This type of lip seal has the lip on the outside of its diameter. As fluid pressure pushes on one side of the lip, it forces the seal firmly against the cylinder wall, moving the piston forward. The lip must be facing in the right direction and sometimes requires a special tool for installation.

Static and Dynamic Seals

Lip-type seals also contain fluid from leaking past transmission and axle shafts. This lip seal type has a lip on the inside diameter supported by a garter spring. The spring applies a constant force as the seal wears.

O-rings: O-rings are used for static sealing. A static seal is a seal between two non-moving parts. A dynamic seal is a seal between two moving parts, like a lip seal. They work great for creating a positive seal against fluid leakage.

Square Cut Seals: Both square cut seals and O-rings fit into a groove. O-rings can roll in the groove when the parts move against each other. Square-cut seals have less movement in this groove due to their square-cut design. They allow for more axial movement than an O-ring.

Metal Ring Seals: Metal seals are used around shafts to provide non-positive sealing. They fit into a groove in a shaft. They have a gap between the ends of the seal, similar to a lock washer. Sometimes, there's a small fastening hook on each end. Teflon seals often come in one circular piece and may require a special installation tool.