ABS Hydraulic Modulator

Many ABS systems run self-diagnostic tests when the ignition is in the ON/Run position. During this system check, the ABS valve modulator can make an audible clicking sound. This sound is normal. Older model vehicles will sometimes make the same clicking noise after the car starts moving.

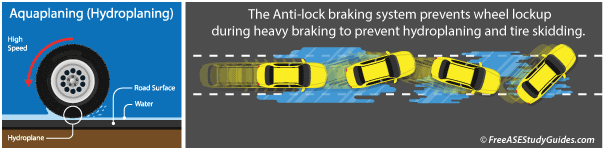

A tire has the most traction just before it begins to skid; some traction and steering are lost once skidding. The wheel speed sensor senses the rotational speed of the tire, and the control module holds or releases hydraulic fluid pressure to the wheel.

For Instance, if a driver is in a panic braking situation and the right front tire begins to lose traction and skid. The EBCM or anti-lock brake control module would sense the difference in the rotational speed of this wheel compared to the others. It would then release/hold pressure to this brake circuit until it achieves optimum traction. This pumping action is faster than any non-bionic human could hope to achieve.

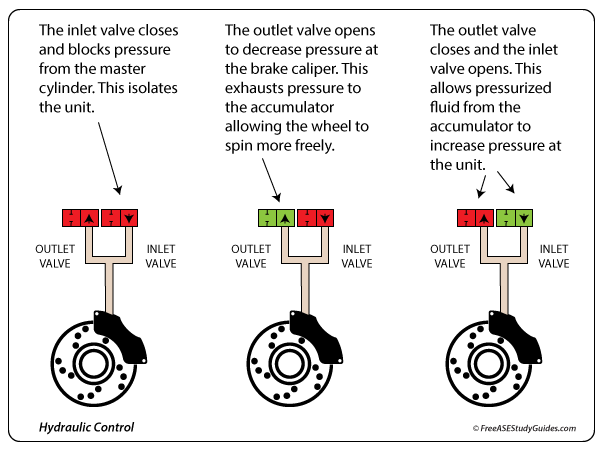

The hydraulic control modulator contains the valves, solenoids, and pistons that control the holding and release of the hydraulic brake circuit if a wheel were to begin to skid. During normal braking, the inlet valve remains open, the outlet valve remains closed, and flow to the brake calipers is unaffected.