Voltage Drop Test

Voltage drop is the quantity of voltage dropped or lost as it passes through a component or resistance in a circuit. Voltage must be present, and the tester leads are connected in parallel with the circuit.

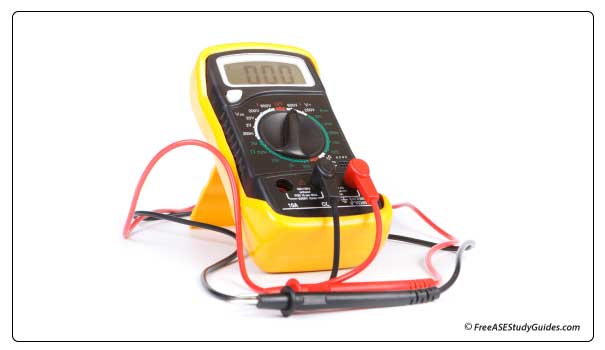

Use a digital voltmeter to find a poor or corroded ground connection. Turn the ignition key on KOEO (key on engine off). Use the service manual to find the key points to probe and set the meter to 1 volt. Connect the negative probe to the battery's negative terminal and back probe the ECM connection at the proper ground wire with the positive probe to identify any corroded, faulty, or poor ground wires and connections.

The typical voltage drop for this type of circuit is below or between 1 and 2 volts. Anything over 3 volts is considered unacceptable, and further inspection is required. ECMs are extremely sensitive; always consult the manufacturer's specifications because testing and voltage tolerance vary from one model to another. A voltage drop test is a great way to find excessive resistance in a circuit.