Transmission Oil Pumps

Transmission oil pumps are either fixed-displacement or variable-displacement. Displacement is the volume of fluid moved by the pump during each cycle. A fixed-displacement pump moves the same amount of fluid with each cycle, and this rate is dependent on engine speed. As the engine's speed increases, the pump's flow rate increases.

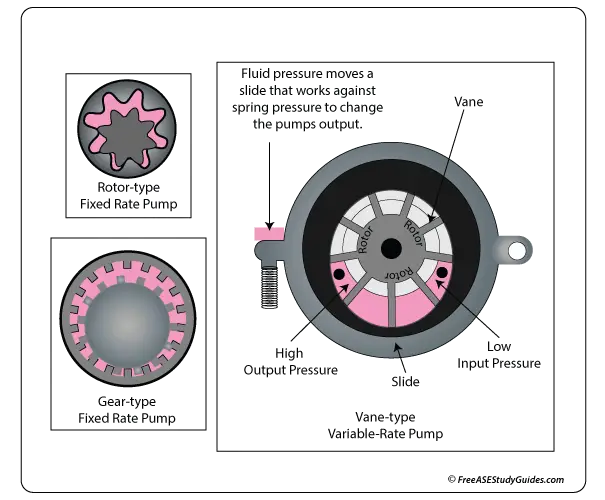

Vane-type: Vane-type variable-displacement pumps use a slide located inside the pump housing to vary the size of the inlet and outlet ports according to the transmission's needs. This slide is moved against spring pressure by a small sample of the pump's output. The pump's slide keeps fluid flow at a minimum when the needs are not as high and provides maximum flow when necessary.

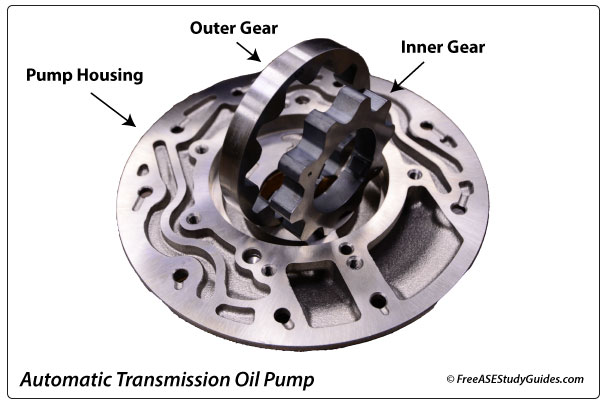

Gear-type: The most common type of fixed-displacement gear pump is the crescent pump. These pumps have two gears like other gear pumps, but they are designed with an outer gear with internal teeth and a smaller inner gear with external teeth. As these teeth mesh, they carry with them and force fluid from the inlet port to the outlet port. The gap narrows as it nears the outlet port. The gears then move the fluid through the outlet port to create transmission line pressure. These pumps have strict tolerances between the gears and the housing. Excessive wear dramatically reduces the output and efficiency of this pump.

Rotor-type: The rotor-type pump is similar to the crescent gear pump, except it has rotors instead of gears. The inside rotor drives the outside rotor. The gap between the rotors increases as it moves away from the inlet port and decreases as the rotor moves closer to the outlet port. Use a feeler gauge to measure these clearances. This action creates the flow to lubricate and operate the transmission's friction bands and clutches. These are also known as fixed-displacement pumps.