Automatic Transmission Bands

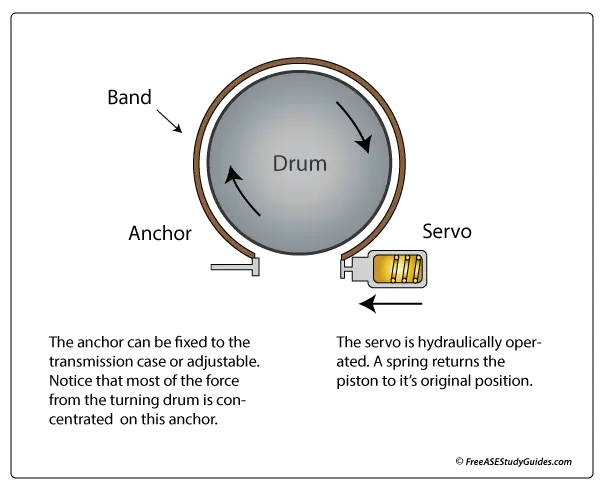

Automatic Transmission Brake Bands are flexible steel plates with organic (cellulose) or semi-metallic friction material. The lining absorbs transmission fluid to aid in heat dissipation. As the band tightens around the drum, ATF flows into grooves cut into the band's surface, helping to cool the fluid as the band brings the drum to a stop.

Some drums are made of a softer iron and easily distinguished by their dimpled surface that aids in clamping and heat dissipation. Drums made of hard metal have a smooth clamping surface.

Bands are either single or double-wrapped. Double-wrapped bands have more clamping force and require less hydraulic pressure to achieve the same stopping power as a single band. As these bands wear, a gap forms between the band and the drum. This growing gap causes the transmission to slip

Hydraulic pressure moves the brake servo. When the servo applies in the same direction as drum rotation, the anchor pin adds to the stopping and holding force. If hydraulic pressure is applied in the opposite direction of drum rotation, the drum works against the servo's pressure.

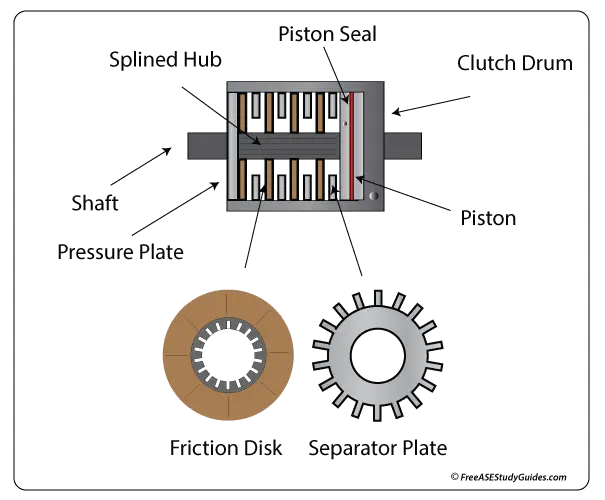

Clutches Drive and Hold

A transmission band is a reaction device in the same family as multiple clutch discs and one-way overrunning clutches. There is a difference. A brake band is strictly a stopping and holding device. Clutches hold and drive members of the planetary gear set.