Superchargers

Superchargers contain roller and needle bearings that rotate over 10,000 rpm. They are belt driven by the engine's crankshaft. The vehicle's exhaust drives a turbocharger. Many consider a turbocharger a free source of boost. A supercharger that takes a little power from the engine to create an additional boost. It is a great trade because they increase horsepower by ~20 %. A supercharger can make a 300 hp engine produce 360 hp.

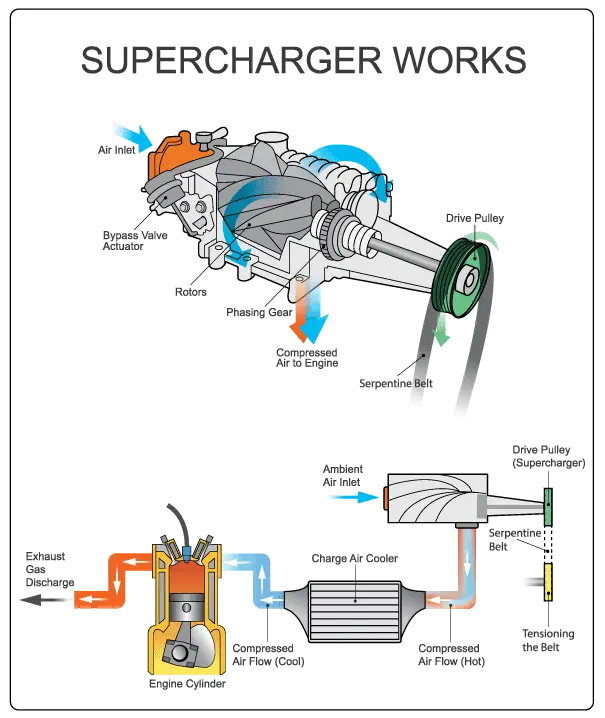

Most superchargers are roots-type, positive displacement pump. They contain a pair of two or three-lobed vanes that turn as the engine turns. As the vehicle is accelerated, they turn in opposite directions of each other. This turning motion pulls air from its inlet and forces it into the engine's cylinders. Heat is created by the air squeezing through the tight gap in the vane lobes. An intercooler cools this pressurized air before entering the cylinders. This cooled charge increases the engine's performance and horsepower.

On many superchargers, changing the size of the pulley changes the speed at which the blades turn. The front bearings contain an opening and a removable dipstick or plug to check and service the special high-speed lubricant. Depriving a bearing of its necessary lubricant results in damage and a noisy squeal.

Instead of the crankshaft, a computer-controlled electric motor drives many of today's OEM superchargers. These superchargers are very precise; engine computers operate valves and adjust boost. It may turn the boost on and off as required. These superchargers are far more efficient than standard superchargers that operate under all conditions.