Automotive Sealants

There are three types of sealant manufacturers commonly use to assemble their engines. These are RTV or room temperature vulcanizing sealant, anaerobic sealant, and pipe joint compound. Of the three, pliable silicone sealants like RTV are most common when repairing or rebuilding an engine. They absorb engine vibrations and fill imperfect surfaces on engine parts.

Do not use RTV sealant on high-temperature components like oxygen sensors and exhaust manifolds. Always use the sealer the engine manufacturer recommends for the specific application.

RTV Sealant

RTV or room temperature vulcanizing sealant is used throughout the engine. An aerobic sealant like RTV cures in the presence of air and forms a flexible rubber gasket. It is important to keep the cap on the sealant when not in use.

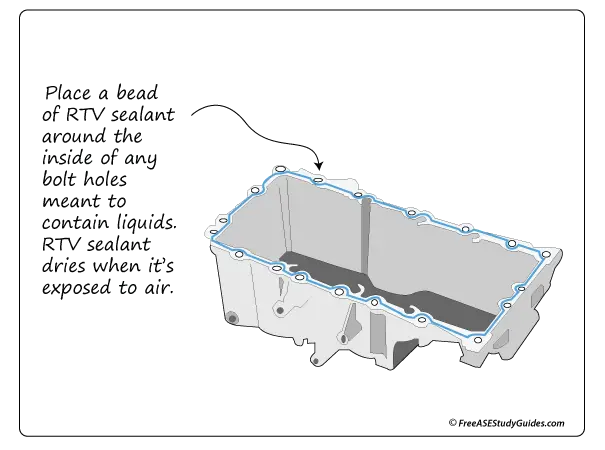

Always clean the surface before applying the sealant, and keep it out of bolt holes. Scrape any old gasket off the surface with a gasket remover, and clean the surface thoroughly for a leak-proof seal. Be careful not to remove any valuable surface from aluminum parts.

Always follow the manufacturer's specifications and procedures when using any sealant around a sensor or actuator. In some applications, RTV sealant fills and seals cracks between engine parts before gasket replacement. Check with the manufacturer for any special procedures. Some parts use anaerobic sealant that cures in the absence of air.