Disc Brake Rotors

Today's vehicles use friction braking systems, producing heat. This heat, combined with normal wear, can warp and distort rotors. As a result, front rotors contain ventilation fins that aid in cooling and circulate airflow. Typically, the solid rotor used on front-wheel drive vehicles' rear brakes is thinner and smaller in diameter.

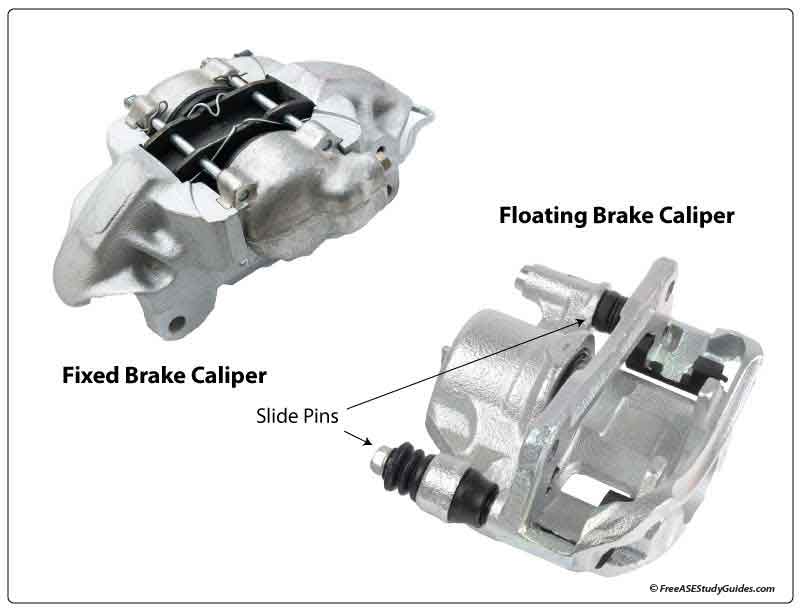

Fixed and Floating Calipers

Two types of calipers are found on today's vehicles. The most common type found on front-wheel drive vehicles uses a floating caliper. It has the hub and rotor cast as two separate parts. This type of rotor is easy to remove and costs less to replace. The other type uses a fixed brake caliper and has the hub and rotor cast into one integral unit.

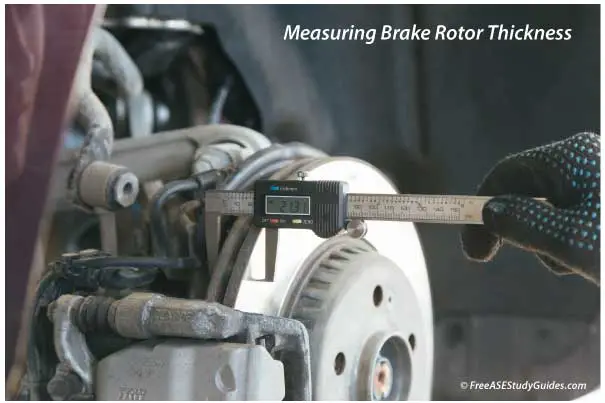

Brake Rotor Inspection

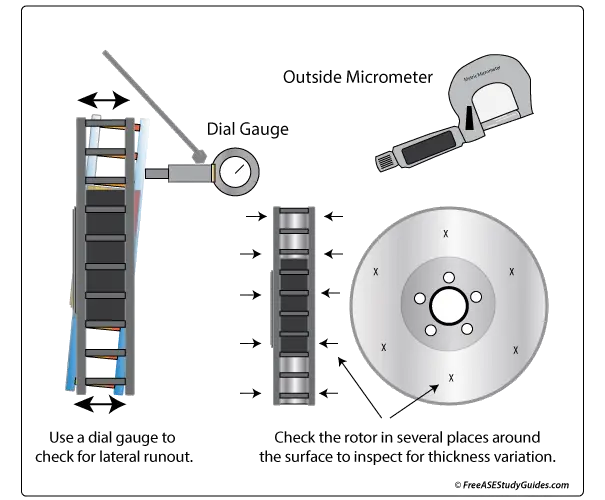

Measure rotor thickness and check for cracks in the surface when deciding whether to replace or machine a rotor. If the rotor shows signs of cracking or is thinner than specifications, replace the rotor.

Check the rotor for runout using a dial gauge and compare it with the manufacturer's specifications. Use an outside micrometer to measure rotor thickness in several places around the rotor. Rotors will become coned or dished from normal wear.

Most rotors are cast iron, and the brake pads are a much softer material. Check for pad deposits collecting around the surface of the rotor. A distortion in the rotor accumulates pad material in that spot.

Resurfacing a Brake Rotor

When a rotor checks within specifications, a brake lathe can resurface and restore the finish. Ensure not to remove too much surface material and bring the rotor's thickness measurements below the threshold. Remove only as much from the surface as needed, and always perform a final slow cut.

The smoother the surface, the better. If you can feel ridges as you move your fingernail or a pen tip across its surface, it must be machined smoother. This roughness wears the pads sooner and may result in a vibrating or humming sound while braking. After machining a rotor, wash its surface with soap and water to remove excess metal shavings.