Brake Shoe Replacement

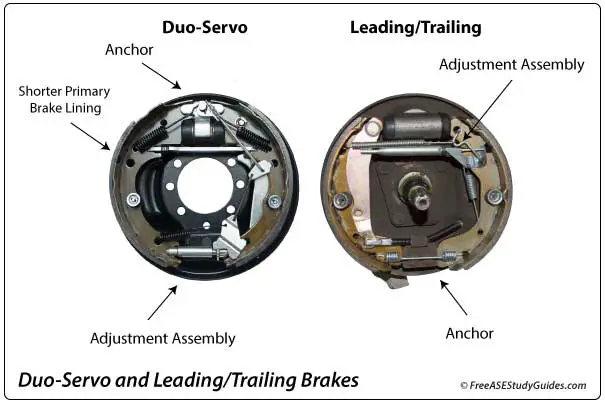

Duo-servo and leading trailing are the two most popular brake shoe/drum designs manufacturers use in today's light trucks and passenger cars. However, the primary and secondary brake shoes are typically different.

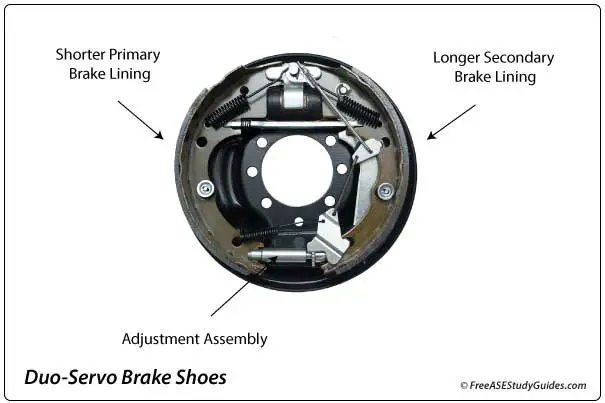

The primary shoe (facing the front of the vehicle) has a shorter lining or contains a different material than the secondary shoe on a duo-servo brake drum system. The secondary shoe is longer because it does most of the stopping. Leading and trailing brake shoes may or may be different sizes.

The secondary shoe of a duo-servo brake drum system is anchored to the backing plate at the top. It's attached to the primary shoe through the adjusting pin at the bottom. As the drum rotates, it drags the primary shoe outward and into the secondary shoe. The primary shoe transfers energy through the floating adjusting assembly to the secondary shoe. The anchor causes the secondary shoe to wedge into the drum, self-energizing and increasing braking power.

It's crucial to place the brake shoes facing the right direction. Reversing the primary and secondary shoes results in noise, brake drag, and a pull in the steering. If unsure, leave the opposite side intact as a reference when replacing brake shoes and hardware.

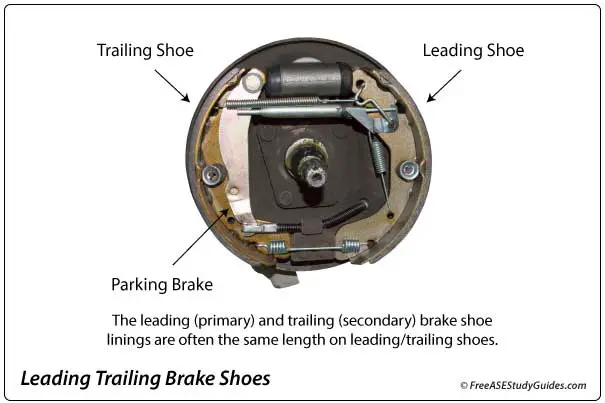

The leading (primary) and trailing (secondary) brake shoes are usually, not always, the same length on leading/trailing brakes. The anchor is at the bottom of a leading/trailing brake backing plate. With this system, the leading brake shoe may wear sooner than the trailing shoe. Front-wheel drive cars with front disc/rear drum brakes typically have leading/trailing brakes on the rear.

Brake shoe linings contain heat-resistant materials mixed with brass, ceramic, and graphite compounds. They can be riveted or glued to the shoe. These materials have replaced the asbestos linings manufactured in the past. The dust from worn brake shoe linings collects in the brake drum. Please note that asbestos is a hazardous material. NEVER breathe brake dust. Assume that every brake system you work with can be hazardous to yourself and those around you, and dispose of any brake dust properly.