Piston Rings

Pistons are slightly smaller than the cylinder bore they fit into in the engine block. It allows for expansion as the engine warms and the pistons fit into their bores. Piston rings fill this changing gap and contain the compression and expansion gases in the cylinder. Most automotive piston ring sets contain two compression rings and one oil control ring. The oil control ring contains three pieces; a spacer and two scraper rings that regulate a thin film of oil that lubricates the cylinder wall.

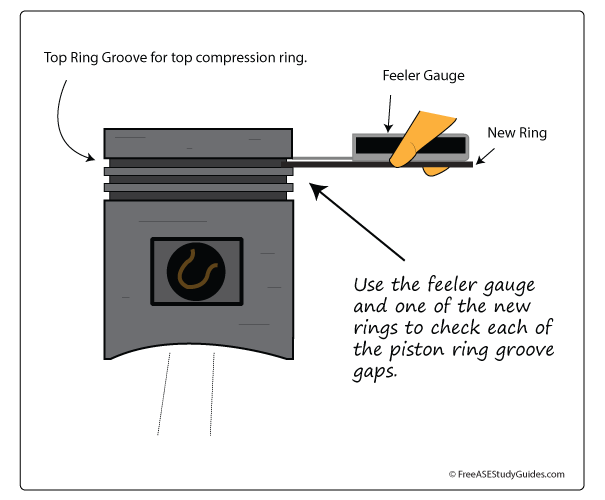

Piston Ring Grooves

The rings fit into grooves machined into the pistons. The two top grooves are for the compression rings, and the bottom groove contains the oil control rings. Clean the pistons in a cold tank and clean these grooves with a ring groove cleaner before measuring. The thickness of this groove is essential. The compression ring grooves allow enough compression to force the ring downward and outward. This force creates the tight seal needed to contain compression and prevent blowby. Use the new ring and a feeler gauge to measure the ring groove's gap. Place the feeler gauge between the ring and the top of the groove. Piston ring groove clearance is typically (.001 - .005).

Compression rings typically have a tapered or barrel shape. Because of these unique shapes, they must face the right direction. Manufacturers stamp a dot or similar mark into the top of the compression ring. It must face upward toward the dome or top of the piston. Check for the manufacturer's specifications before proceeding.

Moly rings are strong and last. They are often installed OEM on new cars and trucks. Most technicians replace old rings with an OEM or original equipment manufacturer's ring set. First, install the oil ring, followed by the second compression ring, and then the top compression ring. Use a piston ring installer to prevent any damage to the new ring. Piston rings are steel, coated with molybdenum (Moly Rings) or chrome. Cast iron rings are common in older engines, and chrome rings in heavy-duty and off-road applications where dirt may enter the intake and scuff the rings.