The OBDII Fuel Trim Monitor

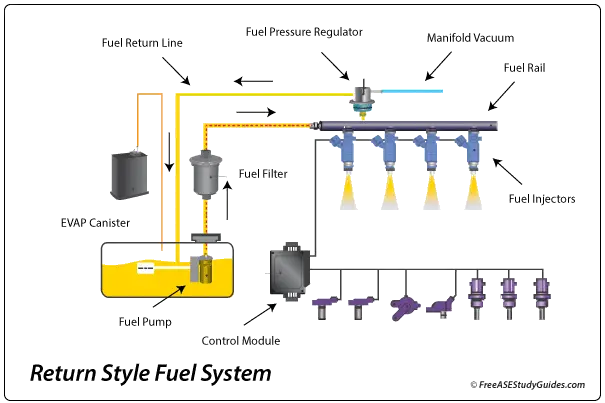

Fuel trim calculations are obtained from the oxygen or air-fuel sensor signals while the system is in closed loop. The driver controls the airflow into the combustion chamber by pressing the accelerator pedal, and the ECM controls the amount of fuel to match operating conditions.

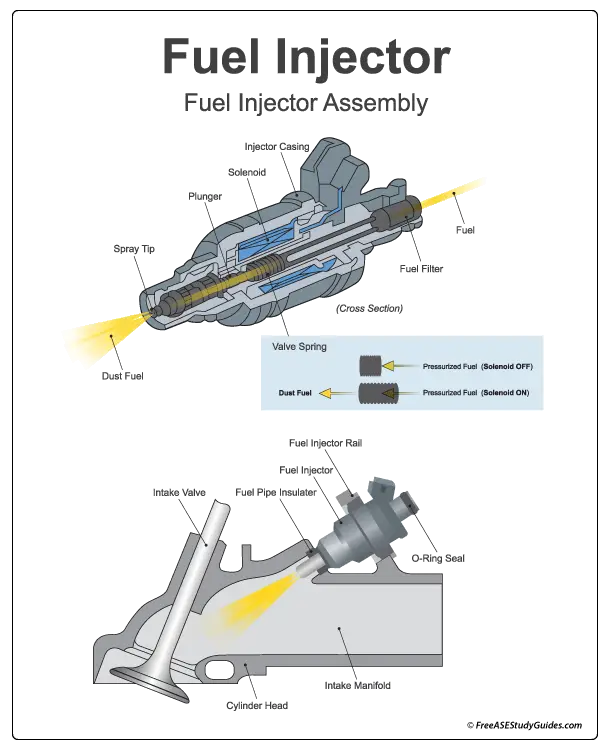

Fuel trim is a method the ECM uses to add fuel to or subtract fuel from the air-fuel mixture. The ECM uses pulse width modulation to adjust the fuel trim by controlling the amount of fuel injector on time. The longer the injector is on and spraying fuel, the richer the air-fuel mixture. The shorter the time the injector is on, the leaner the fuel mixture.

Long Term Fuel Trim

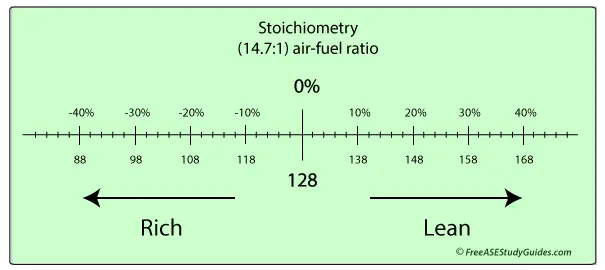

Long-term fuel trim (LTFT) changes as the engine's cylinders wear. The OBDII fuel trim monitor averages fuel trim values. Some systems count steps up to 256 with 128 as stoichiometry, an ideal 14.7:1 air-fuel ratio. A number less than 128 indicates a rich or negative fuel trim and a number higher than 128 shows a positive one.

Others use a percentage; 0% is considered stoichiometry. When LTFT and STFT percentages go beyond 10%, either negative or positive, the ECM sets a fault code and illuminates the check engine light. The ECM calculates LTFT over time and many key cycles. It saves this information for the next time it enters closed loop. Short-term fuel trim is between key cycles.

For example, when a vacuum line is damaged or left disconnected, the oxygen sensor senses this increase in exhaust oxygen. The control module receives this voltage signal and then compensates for the lean mixture by holding the fuel injectors open longer, resulting in a positive fuel trim and an enriched fuel mixture.