Hydraulic Lifter Preload

Adjusting hydraulic lifters is different. With a hydraulic lifter, first set the gap to zero lash and then the preload. This initial zero lash adjustment prevents valve tap and is why these lifters have a quieter operation. With zero backlash, the pushrod should easily rotate without moving up and down.

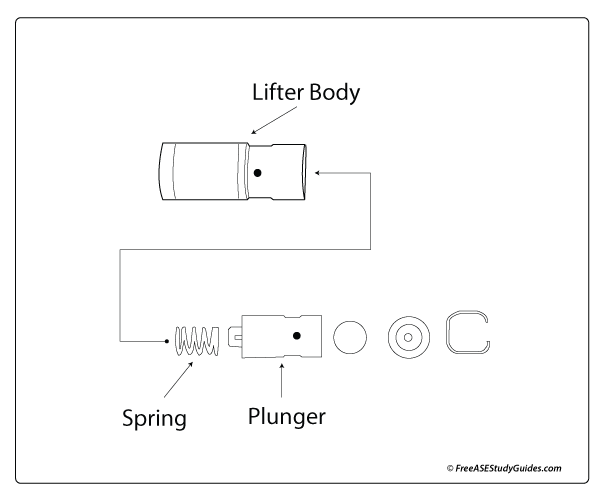

There is a spring-loaded plunger mechanism inside the lifter body. The preload pushes the plunger slightly into the body. If the is preload out of specifications, valve train noise, and a rough idle result. Insufficient preload results in valve train noise, excessive preload results in a low manifold vacuum, and a rough idle.

A sticking plunger will result in a burned exhaust or intake valve that does not close completely. A sticking open intake valve will cause compression to backfire into the intake manifold.

Adjusting Hydraulic Lifters

1. To set the lifter preload, turn the engine in its normal rotation until the exhaust lifter begins to travel upwards.

2. Adjust the intake valve to zero lash and then turn the rocker arm adjustment nut 1/2 to 1 turn. This additional turning of the adjustment nut sets the lifter preload.

3. Rotate the engine until the intake lifter travels completely up and then almost completely down.

4. Now set the exhaust valve to zero lash and turn the rocker arm adjustment nut 1/2 to 1 turn. Check with the manufacturer for special procedures and specifications.

Zero Lash

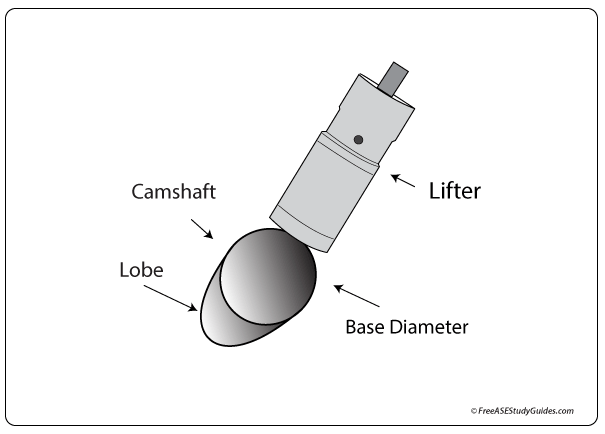

With zero lash (gap), the pushrod should easily rotate in your fingers but have no up and down movement. Sometimes this procedure is easier to perform with the intake manifold removed because you can see the lifter and the heel of the cam lobe. Zero lash is set while the lifter is riding on the cam lobes heel or base-circle. The pushrod must be correctly seated into both the lifter and the rocker arm.