Hazard Warning Lights

The automotive hazard warning system is used to warn other drivers or to indicate a hazard, such as a stopped vehicle in the roadway. It has been incorporated into vehicles sold in North America since 1967. It's part of the turn signal system and sometimes shares the same flasher. A flasher can be bimetallic, solid-state, or hybrid (somewhere in between).

A bimetallic flasher consists of a bimetallic strip, a heating element, and a set of contact points. As power flows through the heating element, it heats the bimetallic strip, bending it. The bending strip opens the contact points, causing a temporary circuit opening. The bimetallic strip then cools and returns to its original position. It then heats up and repeats the cycle until the switch is deactivated. This process is fast and results in the on-and-off flashing of the lights.

A solid-state flasher uses electronic control circuits to control the switch's timing and load output. These devices are larger and cost more than the traditional bimetallic type. They also have a longer life expectancy if they are not overloaded. The bimetallic and hybrid flashers are more durable and can take more abuse.

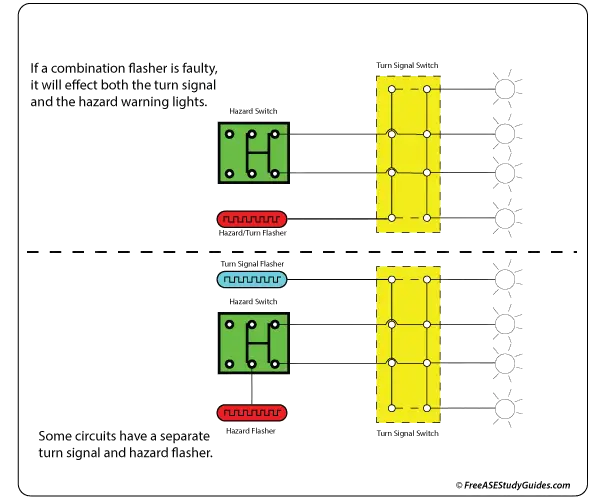

Turn signal flashers, hazard flashers, and combination flashers are designed to serve both the hazard and turn signal circuits. As the illustration suggests, whether a separate flasher is used for the turn signal and hazard circuits depends on the automotive manufacturer. If a combination flasher is faulty, it will affect both the turn signal and the hazard warning lights.