Loose Flywheel Bolts

Flywheels rotate at very high speeds with weight and mass, absorbing the engine pulses transferred through the crankshaft. They are balanced and replaced in the same position as removed.

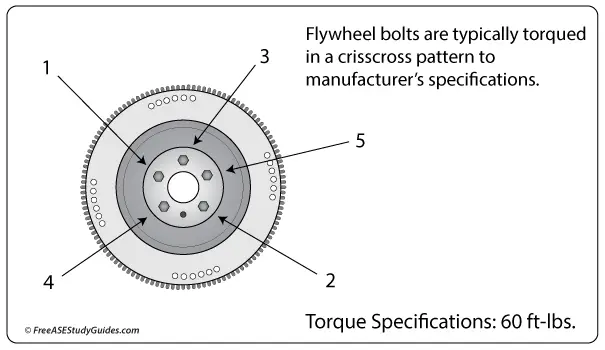

Torque the bolts in a crisscross pattern according to the manufacturer's specifications. Loose flywheel or flexplate bolts make a rattling or knocking sound that changes with engine speed. It is a noise heard behind the engine, where it mounts to the transmission bellhousing.

Manual transmissions have flywheels that absorb engine pulses transferred through the crankshaft, and flexplates provide a replaceable ring gear for vehicles with automatic transmissions. The mass of the torque converter acts like a flywheel, smoothing out engine pulses. Flywheels and flexplates both contain a starter ring around the outside of their circumference. The ring is integral to inexpensive flexplates but can often be removed and replaced on flywheels.

A loose bolt on a flexplate or a crack between the bolt holes can result in the same knocking or rattling sound. If there is a rattling or knocking sound after an engine has been removed and replaced, the flywheel or flexplate bolts may be loose. Remove the small torque converter inspection cover and inspect the part closer if possible.