Intermittent Faults

Loose Connections: A wiggle test is used to indicate if there is a poor connection in a plug, component, or wire included in a circuit. In this illustration, the technician is wiggle-testing an MAF sensor located on the air tube of an engine. Wiggle the plug and wires while observing engine performance. Monitor the datastream function of the scanner and watch for any variations in the sensor's signal.

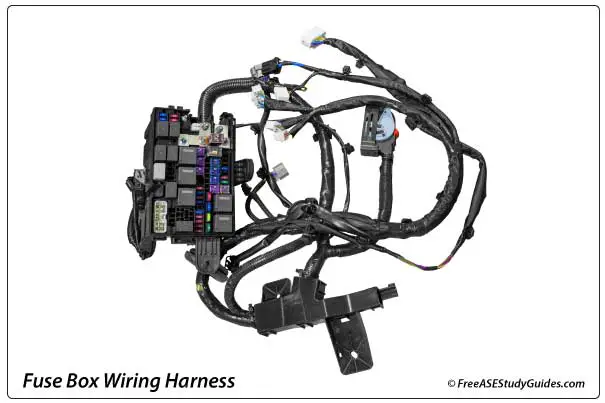

Loose connections wreak havoc on all kinds of systems located throughout a vehicle. A flickering dome light could have a loose plug, wire, or bulb. Today's vehicles have hundreds of connectors, and any loose connection will result in intermittent or no operation.

Repair loose wires and spaded connectors by installing a new female or male connector. The connector may be pinched or soldered to the wire and installed back into the plug. Connectors are usually plastic, and a damaged plug or worn clip may require a replacement that matches the components connector.