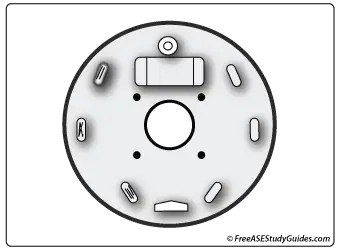

Brake Drum Backing Plates

Steel plate backing plates assemble wheel cylinders, brake shoes, and other hardware onto a drum brake unit. Disc brakes have backing plates as well. If the backing plate gets bent or damaged during a brake job, a squeaking sound occurs as the vehicle pulls away. Just straighten the plate to repair the squeal.

Rear drum brakes have pads that must be level and parallel to the drum surface. These plates are also vital in keeping water, dirt, and debris away from system components.

The shoe pads on the backing plate can become scuffed and grooved as the shoes move back and forth on its surface. These pads can be sanded or filed smoothly to restore surface integrity. When finished, apply a specially formulated high-temperature grease to these pads to protect and reduce brake squeal.

Springs and clips hold the brake shoes in position. These springs create pressure, resulting in grooves and scratches on the plate. Use high-temperature brake lubricant that can withstand the high temperatures of drum braking systems to protect these pads. Avoid petroleum-based greases that can swell rubber parts and chassis greases that burn off and evaporate.

Two types of lubricants are used in automotive braking systems. The silicon-based lubricant works well and protects rubber and plastic brake parts. Hardware lubricants are used for components like backing plate pads. They're synthetic, graphite, or silicon dry film lubricants formulated for high-temperature brake systems.