Cylinder Compression Test

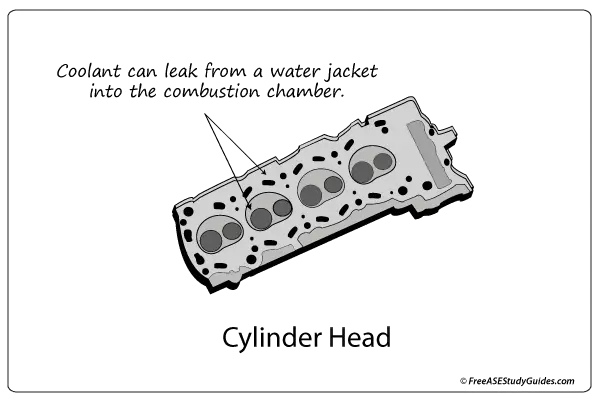

An engine cylinder needs a good seal between the piston rings, cylinder walls, valves, and valve seats. A compression test indicates if an engine has worn piston rings, a bad valve, a leaking head gasket, or if the engine's valve timing is off.

Engine compression test gauges and kits measure a cylinder's compression. Review the manufacturer's manual and (TSB's) technical service bulletins for any special test procedures.

The results of a wet compression test can be quite telling. They indicate a particular area that needs attention.

Wet Compression Test

Worn piston rings/cylinder walls: After running a static test, squirt about a tablespoon of oil into the cylinder and rotate the crankshaft six turns. If the compression increases, the piston rings are at fault.

Burned valves: If, after injecting oil into the cylinder, the compression reading remains the same, then one or more of the valves or valve seats are bad or not seating correctly. Low compression in one cylinder typically indicates a bad valve. Exhaust valves burn most often due to the hot gases passing through. The incoming air-fuel mixture cools the engine's intake valves.

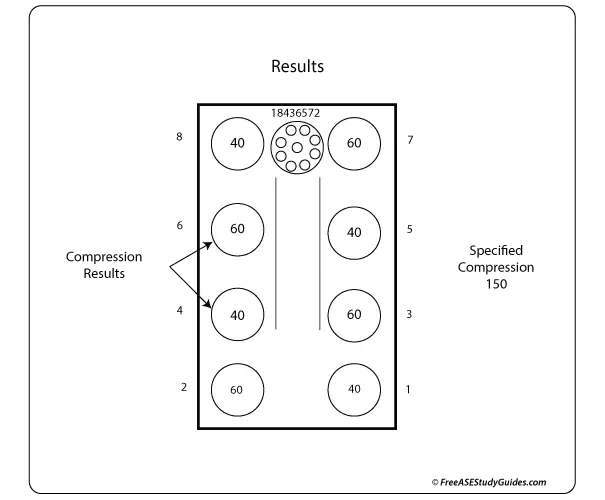

Faulty head gasket: A faulty or blown head gasket leaks compression between two adjacent cylinders. When all the other cylinders are within specifications, and two cylinders next to each other on the same bank are low, a faulty head gasket is likely at fault.

Carbon buildup: Carbon buildup on the top of a piston increases compression readings. Insert a borescope into the cylinder to view excessive buildup.