Vacuum Booster Operation

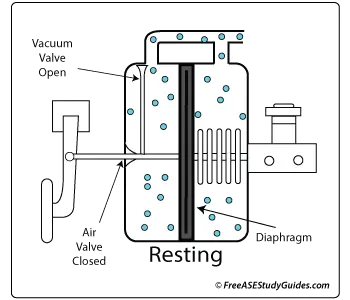

Vacuum brake assist units use a large round flexible diaphragm enclosed in an assembly to create two distinct vacuum chambers. The pedal side of the diaphragm has two valves attached to the pedal arm. These valves work together to control booster operation.

A vacuum brake booster needs the right vacuum to operate correctly. It's typically an engine's intake manifold vacuum (17-21Hg). On some engines, particularly diesel, an auxiliary pump creates a vacuum. This vacuum is applied to both the pedal side and the master cylinder side.

As the driver presses the brake pedal, the vacuum valve blocks the vacuum source on the pedal side of the booster. At the same time, the air valve moves, allowing atmospheric pressure into the chamber. Sometimes, a slight hissing noise is heard as the air rushes past the filter, through the air valve, and into the chamber.

Atmospheric pressure on the pedal side, accompanied by the vacuum source applied to the master cylinder side, produces a powerful brake assist. This is because of the pressure differential caused by the closing vacuum valve and the opening air valve.

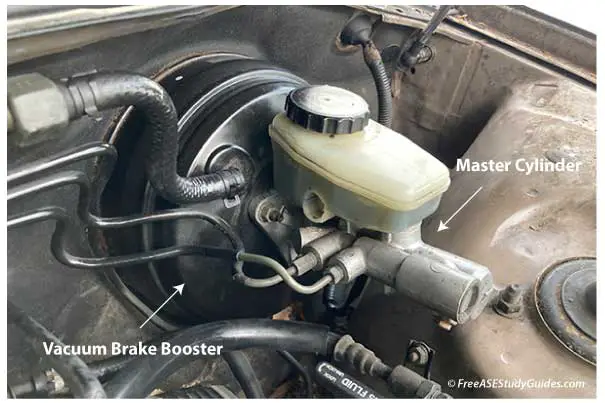

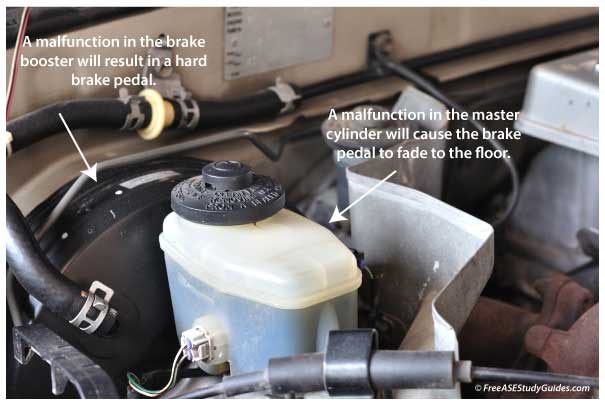

The flexible diaphragm located in the center of the assembly provides an airtight seal. A rod or "power piston" is connected to this diaphragm. This push-rod is mechanically connected to the diaphragm and through the entire unit. One end is connected directly to the master cylinder and the other to the brake pedal. This mechanical connection is why vacuum brake booster failure doesn't result in a complete loss of braking action. There is always a connection between the two.

When the driver releases the brake pedal, a return spring returns the diaphragm to its resting position. While the spring moves the diaphragm, the air and vacuum valves return to normal at rest. This returns the vacuum to both sides of the diaphragm. This is known as a balanced or at-rest position

Brake booster failure results in a hard brake pedal. Vacuum assist brake units require sufficient vacuum to operate correctly. Sometimes, this vacuum is blocked at the intake manifold port or a kink in the check valve hose. Cleaning this port or repairing the check valve's hose restores vacuum and brake booster operation.