Automotive Relays

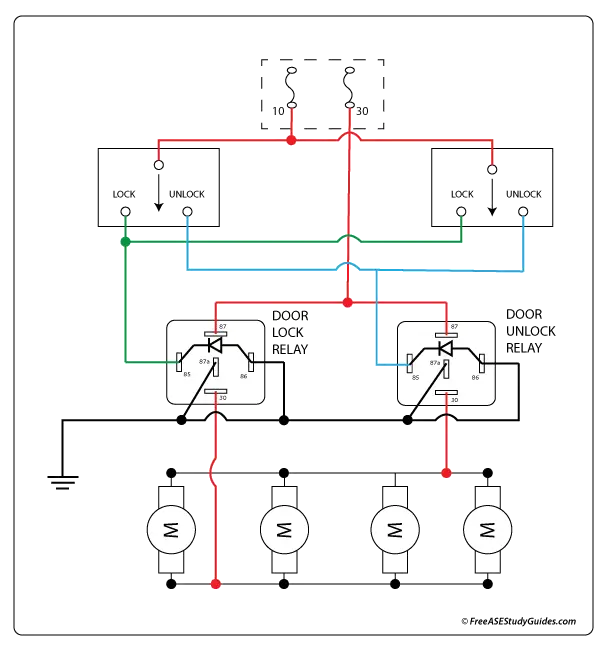

In an automotive electrical system, it is undesirable to have high current and thick wiring running through the dash panel to the horn, switches, and the PCM. Instead, the vehicle's control modules use a low current signal or ground on thin gauge wiring and a relay to activate the door locks, fans, idle control devices, and other high current actuators.

Electromechanical relays are simple mechanical switches. They require low current from a component like the BCM or PCM to activate. When low current passes through the relay's coil, a magnetic field connects the high current circuit.

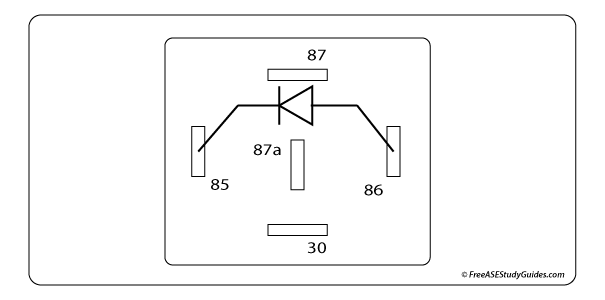

This requires two separate components: the switch and the coil to activate it. The #85 and #86 terminals are used as electromagnet control. The coil usually contains a clamping diode to protect the contacts and other circuits from the sudden current collapse when power is removed. On some circuits, it's important not to reverse these two pins. The #30 pin is connected to a high current source, and number #87a (SPDT) is the terminal where the arm parks (NC). The #87 pin sends the power to and activates the circuit's load (component).

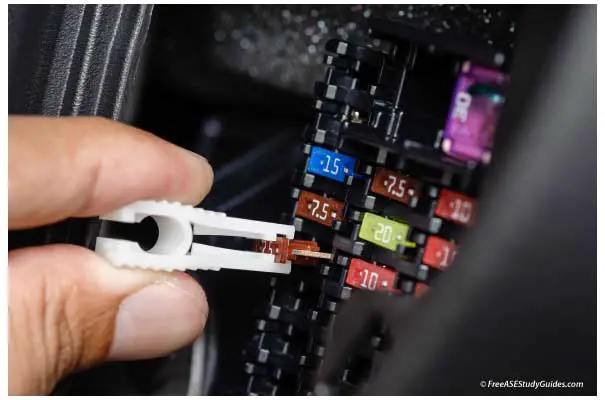

Automotive manufacturers have used them instead of switches for years. They're simple to diagnose. Like fuses, they are conveniently placed in a central location for easy identification and replacement.