Air Spring Suspension

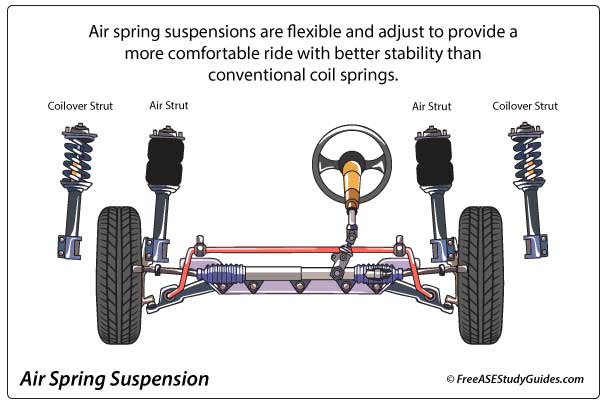

Air spring suspensions have control modules with height sensors. They adjust to provide a more comfortable ride with better stability than conventional coil springs. Replacement air spring components are more expensive than coils, contain electronics, and can form line and bag leaks as the suspension ages.

Air Springs

Air Springs: In an air suspension system, air springs or air struts replace coil springs, torsion bars, and leaf springs. Air spring failure can result from the environment, age, or moisture from a saturated compressor drier. This moisture affects other components in the system.

They also fail because the rubber dries out, especially at the base where the bag folds. Spray soapy water around the base and where the quick-connect o-ring connects to the line when inspecting an air spring for leakage. Watch for bubbles on the springs, connections, and tubing.

Solenoids

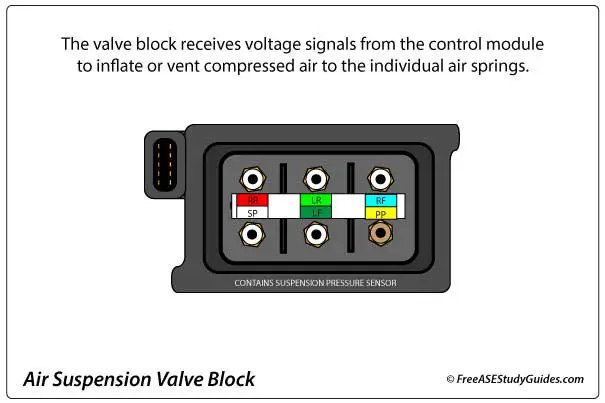

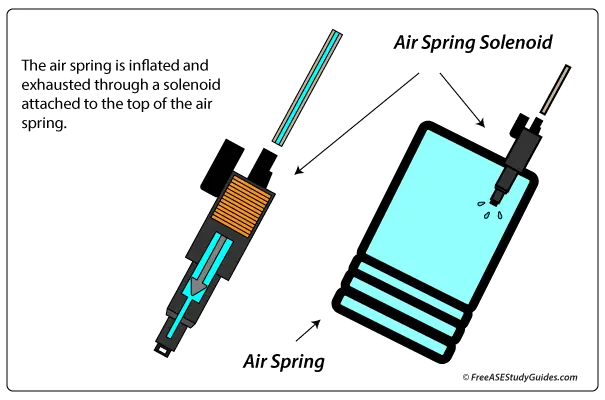

Solenoids: The air spring solenoid valves are combined in a block or at each air spring or strut. These solenoids are electrical and can have an input or an electrical problem.

Solenoids at the spring typically suffer from air leaks at the connection where the quick-connect o-ring connects to the line. They can also leak where the solenoid connects to the air spring. Always follow the manufacturer's procedures for removing the solenoid and specifications for testing circuits.

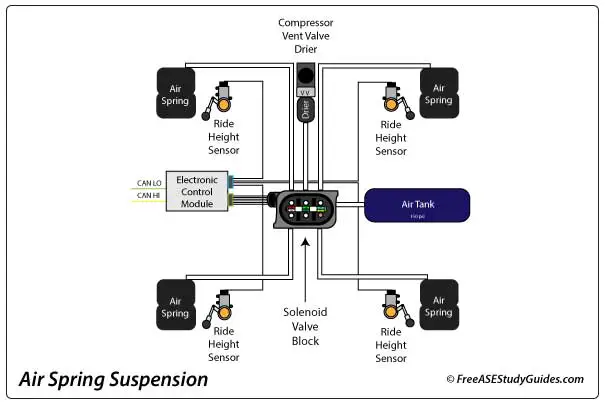

The electronic control module opens the valve to the air tank and the valve to the air spring to inflate the spring. The module opens the vent valve on the compressor and the solenoid on the air spring or in the valve block to deflate the spring and vent the air to the atmosphere.

Air lines

Air lines: Air suspension tubing consists of 1/4 and 3/8 inch nylon tubing approved for use in airbag systems by the Department of Transportation (DOT). These lines wear and can become damaged by scraping across sharp chassis and suspension parts. Use soapy water to trace a leak en route to the problem air spring.

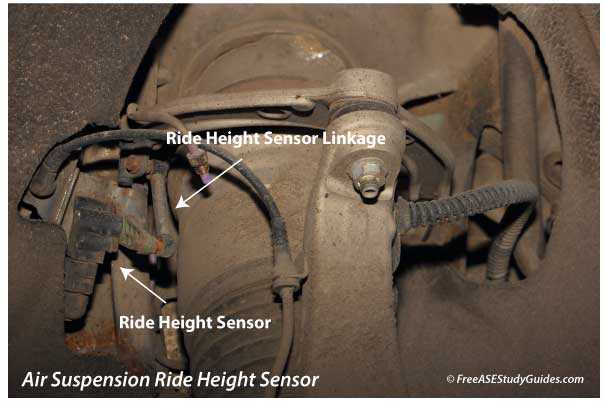

Ride Height Sensors

Ride Height Sensors: The air suspension system uses input from the ride height sensors to adjust vehicle ride height. The arm on the height sensor moves as the body moves up and down. For instance, if passenger and cargo weight lowers the vehicle's rear, the vehicle lowers toward the ground, and the arm of the sensor moves. The control module receives the signal and turns on the compressor or opens the valve to the air tank and the valves to the rear air springs in the valve block to inflate the rear springs.

Computer Controlled Compressor

Compressor: In time, the system's compressor wears, especially if there is a leak in the system. The compressor burns out, attempting to maintain air pressure in the leaking system. Some of these have a failsafe. These newer factory systems are computer-controlled. Use a scanner to retrieve any codes identifying which part of the system to troubleshoot. The system connectors are often next to the computer in the trunk; disable the system with the switch located by the scan connector before raising a vehicle with air suspension.