Variable Displacement Compressor

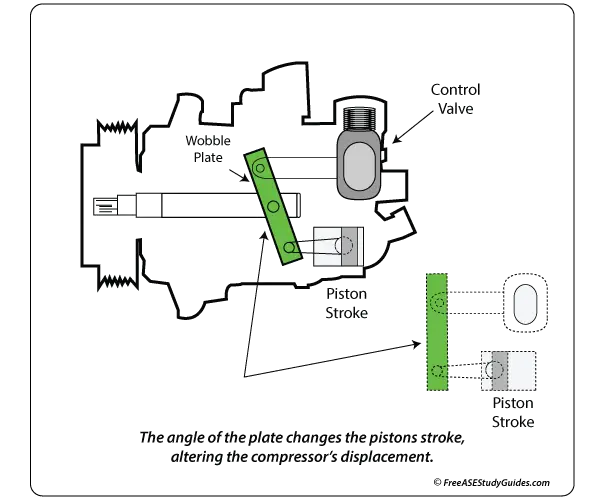

A variable displacement compressor eliminates the need for a cycling clutch by altering the compressor's volume based on system demands. The system's clutch is left engaged while the system is in use. They are disengaged if there's a problem or shut down. There is no cycling clutch switch to cycle the compressor on and off. Changing the pistons' stroke changes the compressor's displacement or output.

The pistons are attached to an axial wobble plate that changes its angle based on the difference in pressure between the top of the piston and the housing. When cabin temperatures are warm and air conditioning demand is high, the low side pressure is also high. During this time, the compressor's wobble plate is moved to its greatest angle, increasing the piston's stroke and providing maximum refrigerant displacement. As demand decreases, the wobble plate is moved to a lesser angle, providing lesser or minimum output.

The control valve connected to the suction and discharge ports may be mechanically or computer-controlled. The mechanical valve has a diaphragm that responds to changes in low-side pressure. It increases piston stroke as it opens, increasing the volume or displacement of the refrigerant's flow through the compressor.