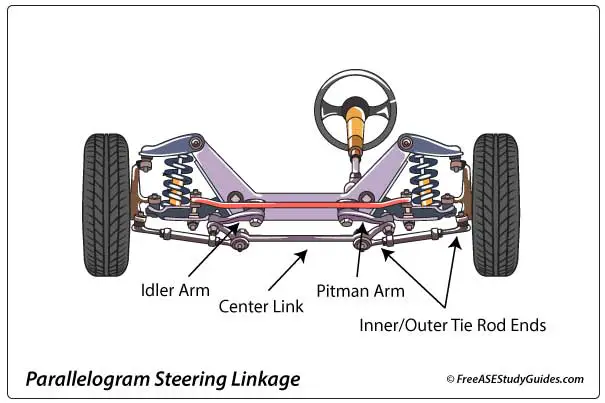

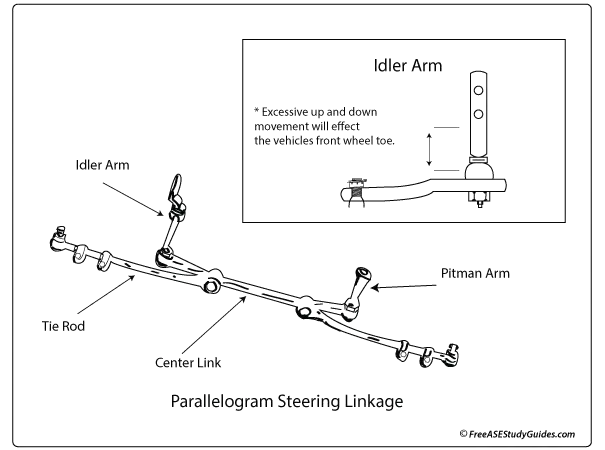

Idler Arms: Parallelogram Steering Linkage

Parallelogram steering systems have an idler arm opposite the pitman arm that fixes the center link, preventing it from moving and flexing as the vehicle travels over bumps and turns in the road. Today's vehicles typically have a parallelogram or rack and pinion steering system. The parts of parallelogram steering systems include the pitman arm, center link, idler arm, and two tie rod links.

The idler arm is designed to keep the center link parallel to the road surface while allowing the connection to swivel both left and right. The pitman arm is attached to the gearbox; it turns the center link as the driver steers the vehicle. The idler arm provides for swivel movement and resists up and down movement. This resistance is vital in maintaining a vehicle's toe setting.

A vehicle will begin to shimmy when the steering linkage gets loose. The steering wheel will feel loose and sloppy. The linkage system consists of links with tapered holes and tapered ball joints fitted together and torqued to a specified amount. When the joint studs get loose in their bores, the holes enlarge, and looseness occurs.

Sometimes, the idler arm has bushings between the frame and the mount. These bushings, as well as the mounting bolts, should be checked for wear and looseness. Some mounts have adjustable slots. Always mark these slotted mounts before removal.