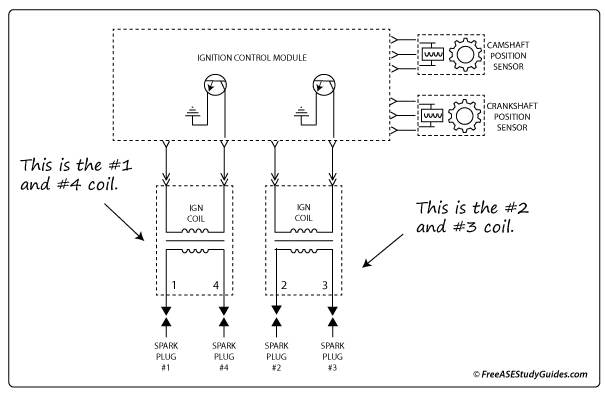

Waste Spark Ignition

Some engines have ignition systems with coil packs that fire two cylinders simultaneously, known as the waste spark method. One cylinder is on its compression stroke, and the other is on its exhaust stroke. The sparkplug that fires during the compression stroke creates power, and the sparkplug that fires during the exhaust stroke is "wasted" because it fires into inert exhaust gases.

These ignition systems are significantly better than older ones, with one coil providing the spark for all the engine's cylinders. However, because of their design, a faulty coil results in a misfire on two cylinders. Scanned data will indicate two misfires; a six-cylinder engine may simultaneously have misfires on cylinders #2 and #5 or #1 and #4.

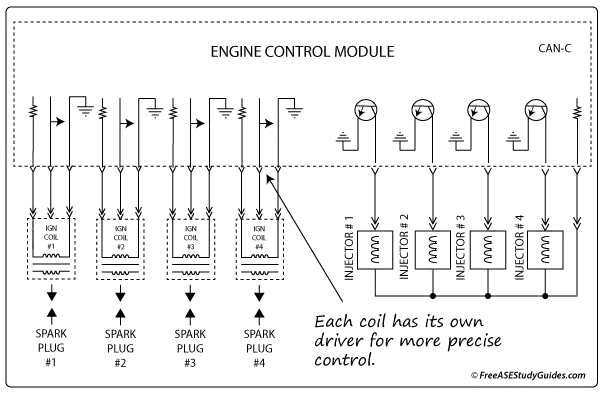

Most of today's engines have (COP) coil-over plug ignition systems. These ignition systems are more efficient than single-coil or waste spark ignition systems. The ignition module in the ECM or the coil controls on time (dwell). Limiting the amount of dwell reduces unwanted heat when demand is low but still provides full saturation for acceleration, a heavy load, and passing. In addition, COP ignition systems offer better performance because the ECM controls each cylinder individually.